Shortcuts

Tags

Latest Posts

Shunt Resistor versus Hall Effect Technology

Measurement of Large DC Currents

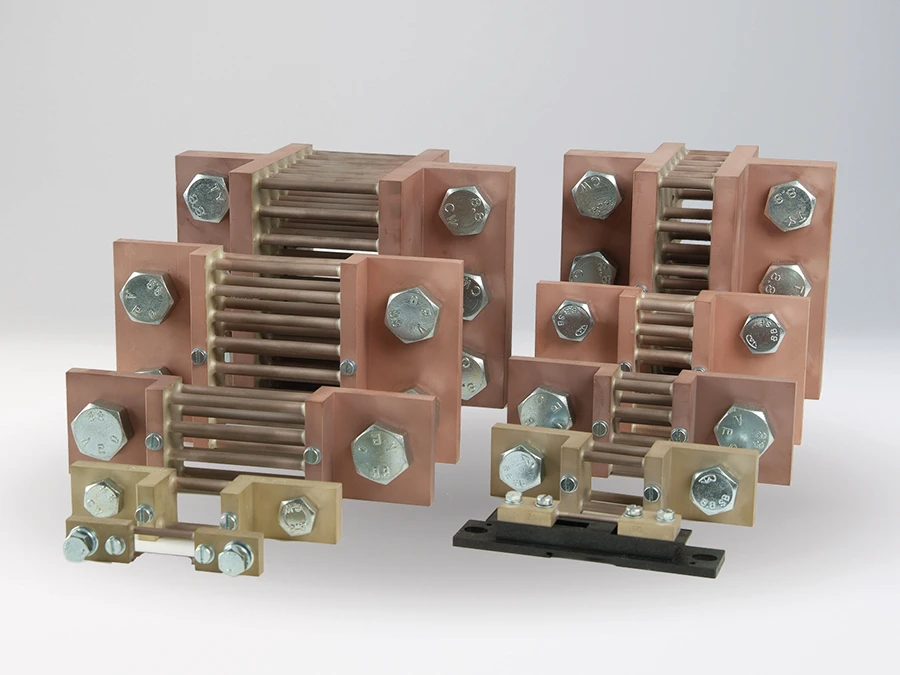

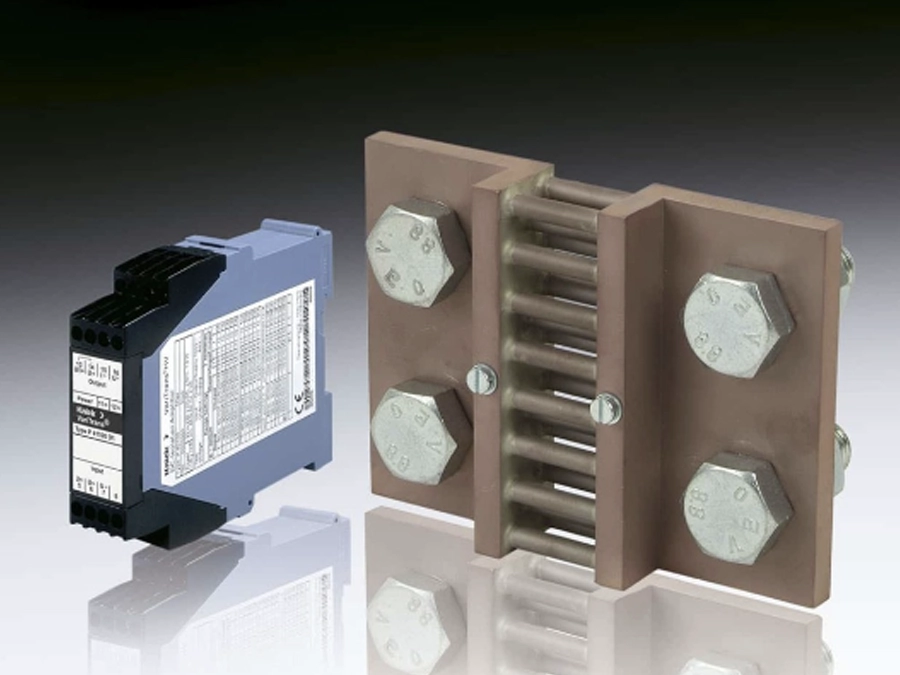

There are many systems where measurement of large DC currents are needed for performance and safety. Two examples are static excitation and rail traction power. These current measurements are often made by one of two main principles: shunt resistor with mV transducer or Hall effect feed-through sensor.

Both sensor principles have existed for decades. For this reason, commercially available sensors of both principles can be regarded as time proven. However, each have their pros and cons, and are mainly tied to the physics of the principle used. If the disadvantage of a sensor is inherently bound to its physics, it is hard or impossible to overcome the problem, regardless of the number of iterations or design changes it has gone through.

If accuracy of the measurement is of particular importance, shunt resistor designs have relevant advantages. Even with documented accuracy specifications, far-field influences of neighboring conductors and sensor position make it almost impossible to assess the total measurement error of a non-contact Hall sensor.

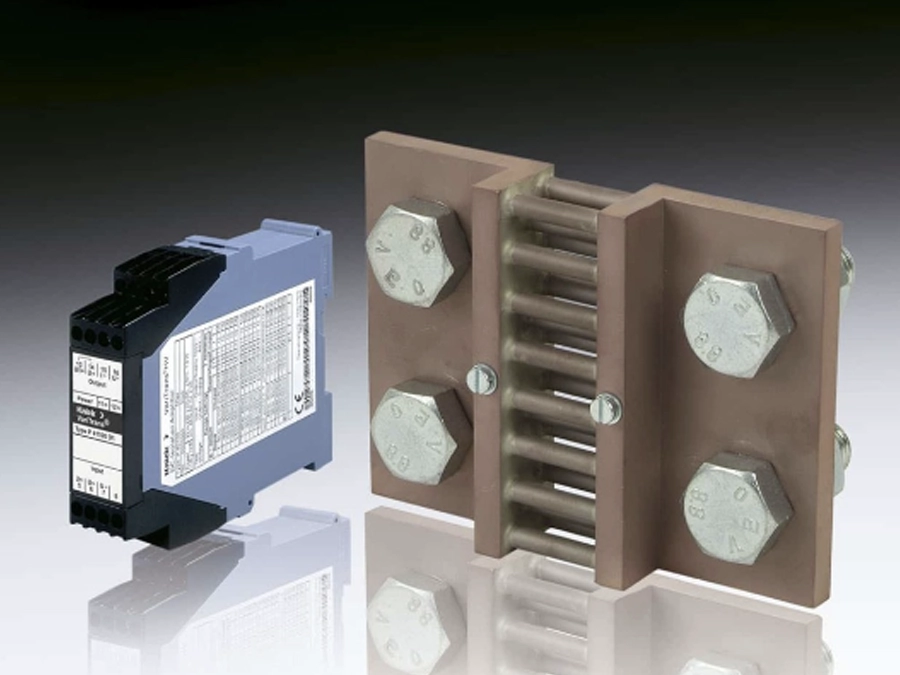

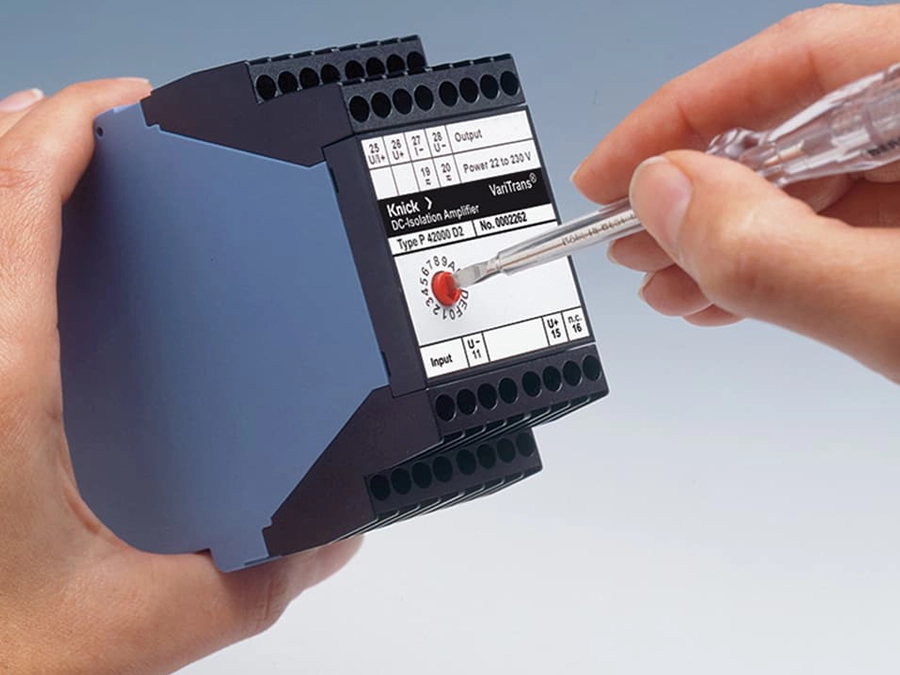

However, if size minimization is necessary for an installation, then Hall effect sensors, with an overall smaller total footprint, could be considered. This is due to shunt measurement requiring a two-piece system, the shunt resistor, which would have a footprint directly proportional to the amount of current being measured, coupled with a corresponding mV transducer.

Conclusion

If ensuring accuracy with current measurements is of primary importance, then a shunt resistor with a corresponding mV transducer is likely the best option to consider. Due to the effects of various external influences such as temperature, positioning of sensor and conductor, stability and coupling of auxiliary power supply, and high current events that might be eventually seen, the initial and sustained accuracy of Hall effect sensors is very difficult to assess.

If other considerations within an application outweigh the benefits of accuracy seen with a shunt and mV transducer package, then Hall effect sensors could be further evaluated. This might include a project where space is limited to incorporate a shunt, and where this available space might heat up if a shunt were to be housed within it, due to power dissipation.

However, convenience with the installation and downstream maintenance should also enter into decision making. Here, the shunt and mV transducer show further advantages, due to compatibility with standard control systems, and ease with initial mounting and potential replacement.

The following chart offers a further comparison of the two technologies, with advantages for each technology highlighted in green, accordingly.

Steve Allard

General Manager at Knick Interface LLC, USA

Phone: +1 888 62 KNICK

Latest Posts

Process Analytics

Pharma, Sensor, Conductivity

Interface Technology

Hydrogen

Interface Technology

Interface Technology

Exhibition, InnoTrans

Process Analytics

Achema

Related Posts

Sept 2024

Interface Technology

Hydrogen

Stack and String Voltage Measurement in Electrolyzers and Fuel Cells

Sept 2024

Interface Technology

New 30 mV Shunt Resistors for Knick Transducers

Sept 2024

Interface Technology

Exhibition, InnoTrans

Innovations at InnoTrans 2024 for rolling stock and DC traction power supply

May 2022

Interface Technology

Energy

Energy storage - the handshake between renewable energy and electric vehicles

Feb 2022

Interface Technology

P52000VPD, Voltage

P52000VPD voltage presence detector reliably detects voltages up to 4200 V DC

Sept 2021

Interface Technology

USA, Exhibition

Knick Interface at Battery and Electric & Hybrid Vehicle Technology Expo

May 2021

Interface Technology

Quadruple Standard Signals in Just One Signal Conditioner

Apr 2021

Interface Technology

Hydrogen

Electrical measurement and process analytics for hydrogen production

Mar 2021

Interface Technology

High-Voltage Transducer, USA, P44000

Condition Monitoring of High-Voltage Motors

Mar 2021

Interface Technology

Pulse frequency conditioner for speed sensors

Nov 2020

Interface Technology

High-Voltage Transducer, Voltage, P42000D2

Worldwide smallest transducer up to ±2200 V

Aug 2020

Interface Technology

DC

Importance of broad-range power supplies for DC electrical measurement

Jul 2020

Interface Technology

High-Voltage Transducer, DC, P29000

Measuring Photovoltaic Degradation

Jun 2020

Interface Technology

High-Voltage Transducer, USA

Electrical Measurement Solutions: Control from 480 to 4800 Volts

Jun 2020

Interface Technology

High-Voltage Transducer

Benefits of High Voltage Transducers versus Instrument Transformers

Nov 2019

Interface Technology

DC, USA, Current

Shunt Resistor versus Hall Effect Technology

Mar 2018

Interface Technology

MTBF beyond 3000 years: A snap hook for your plant

Jan 2018

Interface Technology

UL

Knick Products Comply With UL - What Does That Mean?

Nov 2017

Interface Technology

High-Voltage Transducer, P50000

High-voltage transducer offers more safety on railway vehicles

Feb 2017

Interface Technology

P41000TRMS

True RMS Measurement with P41000TRMS

Feb 2017

Interface Technology

P22400, SIL