Food and Beverages

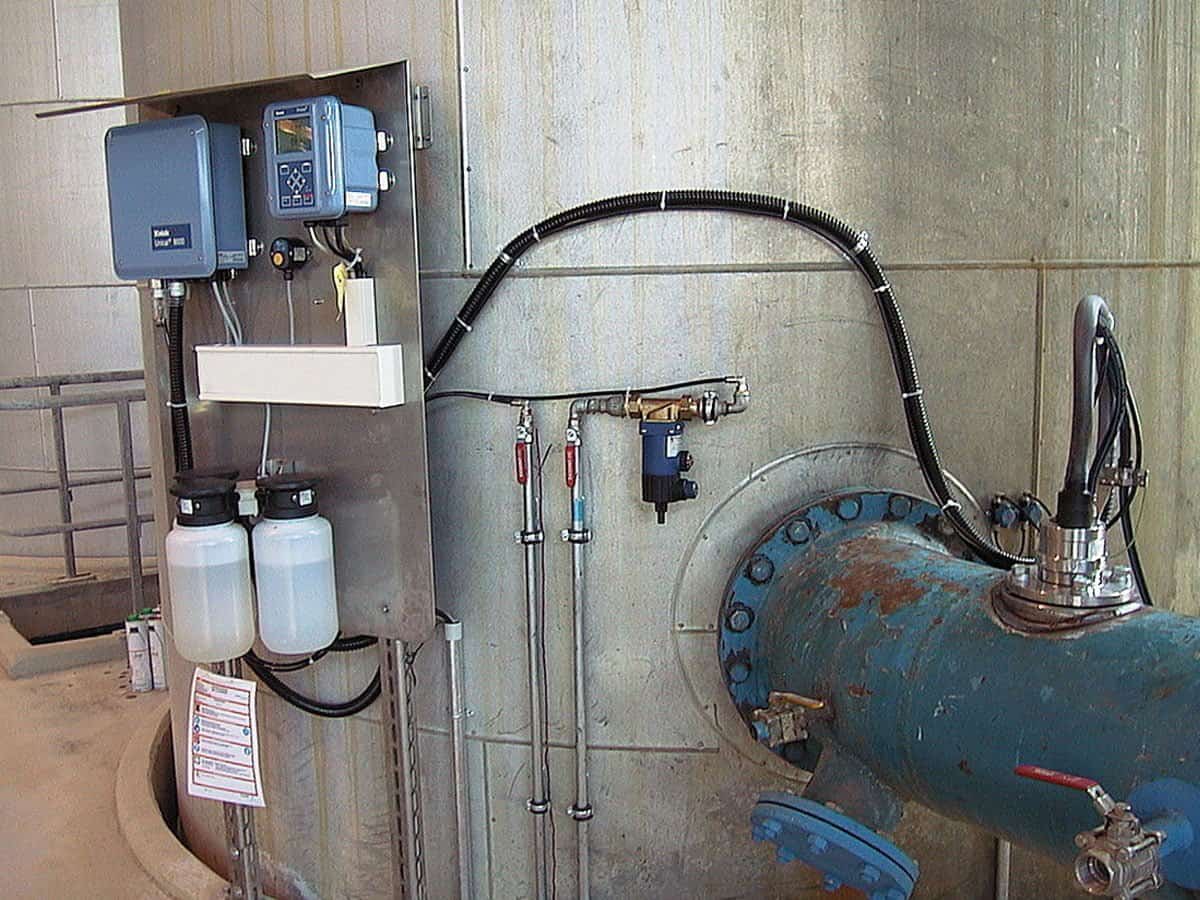

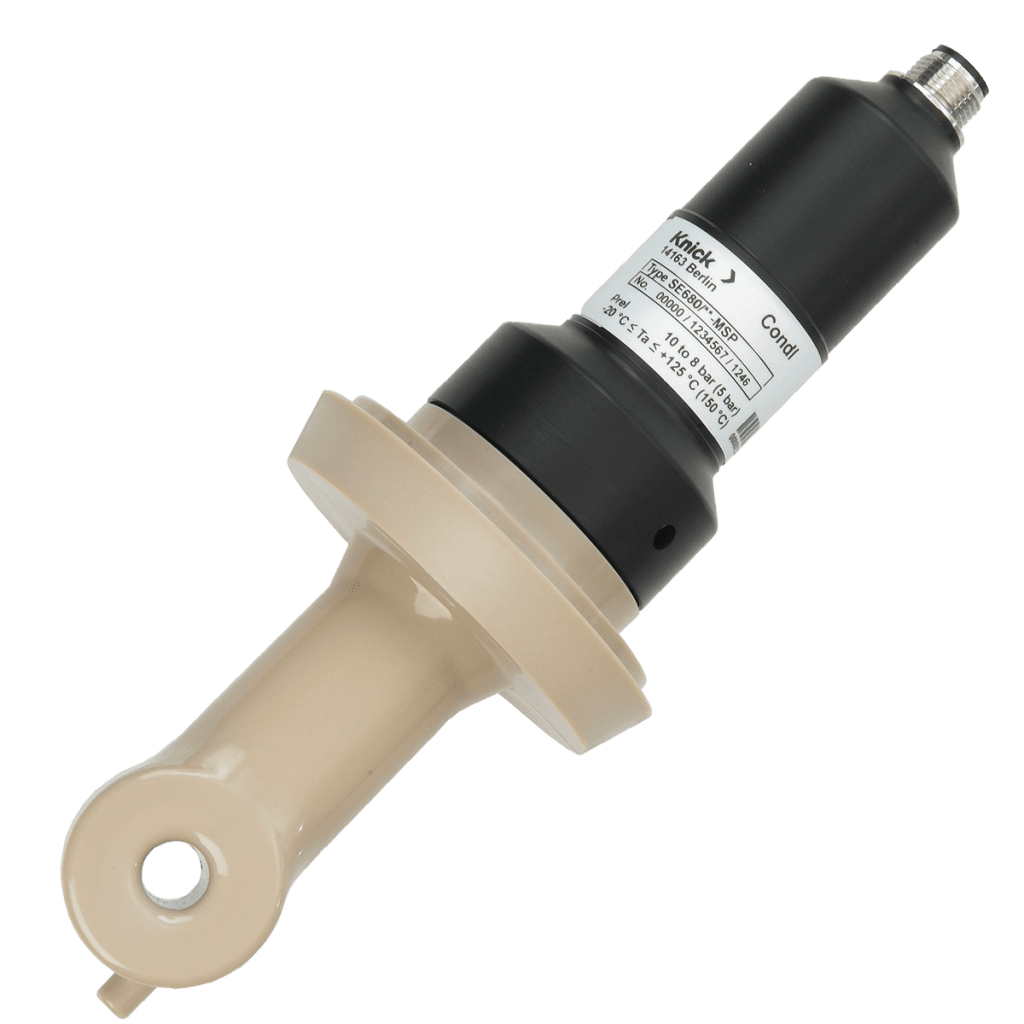

Knick advises and supports companies in the food and beverage industry around liquid analysis with process reliability. pH, oxygen, and conductivity are the most frequently used critical parameters for optimizing these processes.

With a wide product range of sensors, industrial transmitters, fittings, and cleaning and calibration systems, Knick provides custom solutions and services.

Product Safety and Quality Remain a Major Challenge

Quality assurance in the food industry consists of monitoring and controlling various parameters in order to ensure that the products meet the desired quality standards and are safe to ingest.

The requirements for measuring technology include all hygienic aspects (SIP and CIP capability), preventing glass breakage, and continuous measurement since food is produced on many lines with high throughput. At the same time, fats, oils, and viscous media make it difficult for sensors to work. Here, the trend is toward fully automated measuring loops that include the cleaning and calibration of pH sensors.

Beer Brewing

Sugar

Dairy

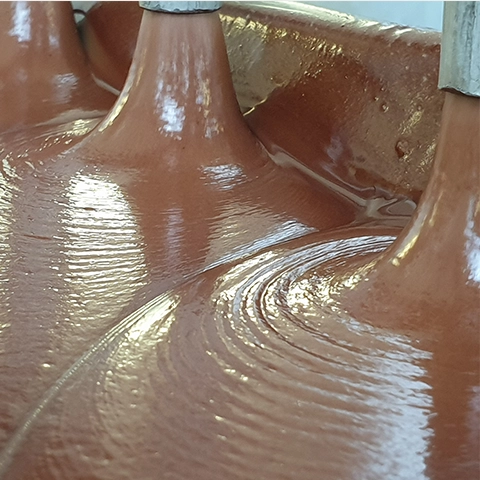

Chocolate

Why Knick?

Knick supplies everything from portable transmitters for the laboratory or sample measurement in the field to fully automated in-line measurement solutions with sensor maintenance – everything from a single source. Of course, they are hygienic, safely isolated from the process, and glass-free.

Related Applications

Do you have more questions? We are here for you.

Contact us!