PROCESS ANALYTICS

Monitoring Raw Water Inlet

Monitoring the Raw Water Supply for Drinking Water Treatment

Quality control of the raw water used in the treatment of drinking water is key. Often, the budgets for municipal drinking water treatment are tight.

This is why system operators are faced with the challenge of implementing safe processes for producing clean water while complying with strict cost calculations.

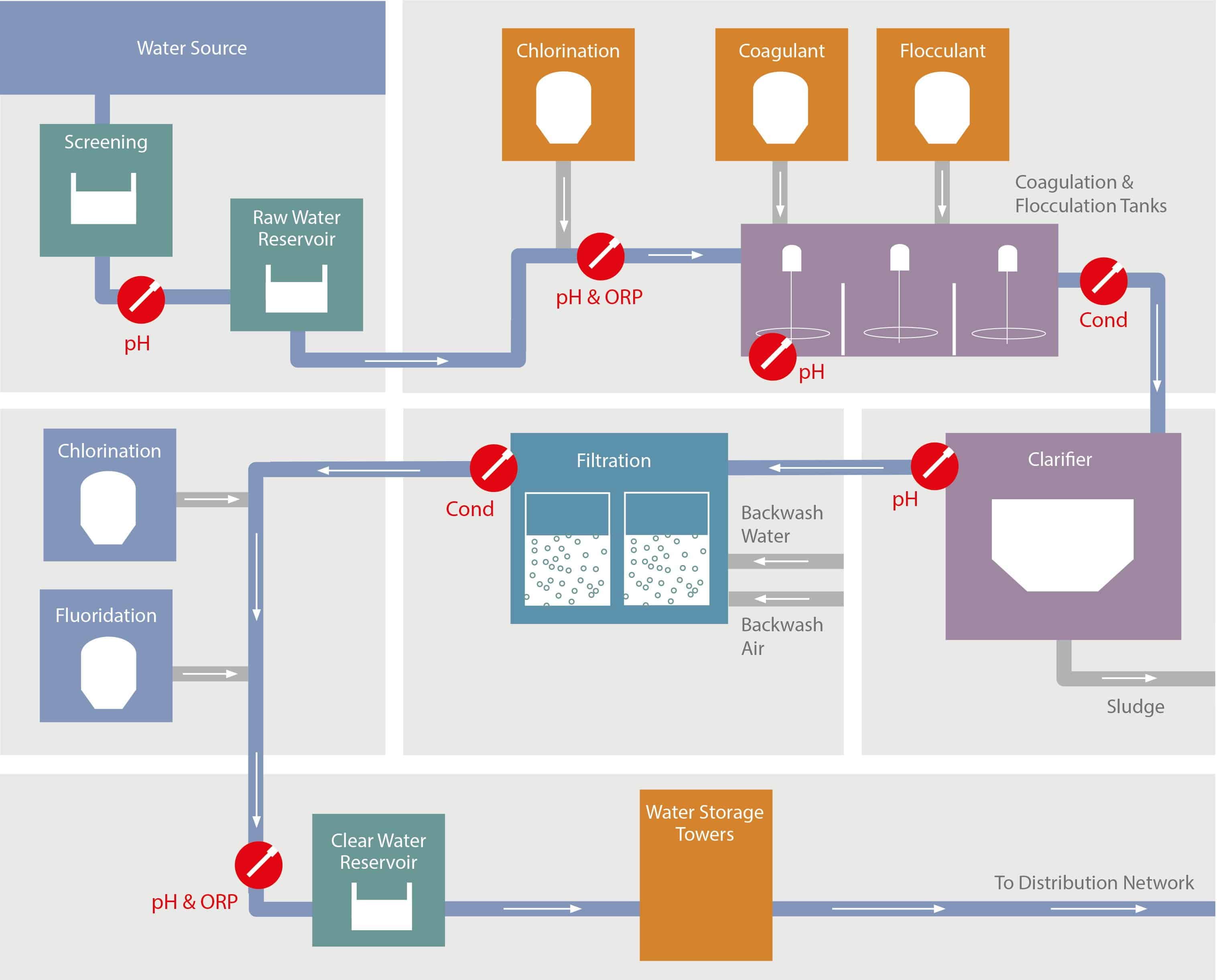

The online measurement of pH value and ORP enables operators of drinking water treatment plants to evaluate the quality of the raw water supply and take measures to protect the plant.

Importance of pH and ORP Measurement in Drinking Water Treatment

Before the raw water from lakes, rivers, or wells can be fed into supply lines as drinking water, its harmlessness is ensured by different analyses and filtration procedures. Although certain concentrations of germs and pollutants can only be documented in continuously implemented, complex offline analysis procedures, technicians receive important information about the water quality and the steps that must be taken, if any, through the online pH and ORP measurement of the raw water supply.

Acquiring the raw water values plays a key role in the overall drinking water treatment process. Measures for neutralizing extreme pH values or redox potential are not only taken in the spirit of being compatible with health. They also protect the treatment plants and filters against premature wear. Acidic water is unhealthy and has a corrosive effect on water pipes.

On the other hand, redox potential describes the concentration ratio of the reduced and oxidized substances in water. They include nitrate, sulfate, and manganese oxide. Further, a low redox potential means that the risk of microbial contamination is significant. To increase redox potential and in turn, disrupt the germination process, chemicals with an oxidizing effect like chlorine are added to the water. Their metering is based on ORP measurement, and both underdosing and overdosing must be avoided by reliable measurement acquisition.

In cases of underdosing, not all germs are killed. Overdosing, on the other hand, accelerates plant part wear, requires additional treatment steps for the health-compatible reduction of the chlorine concentration, and leads to excessive, uneconomical chemical consumption.

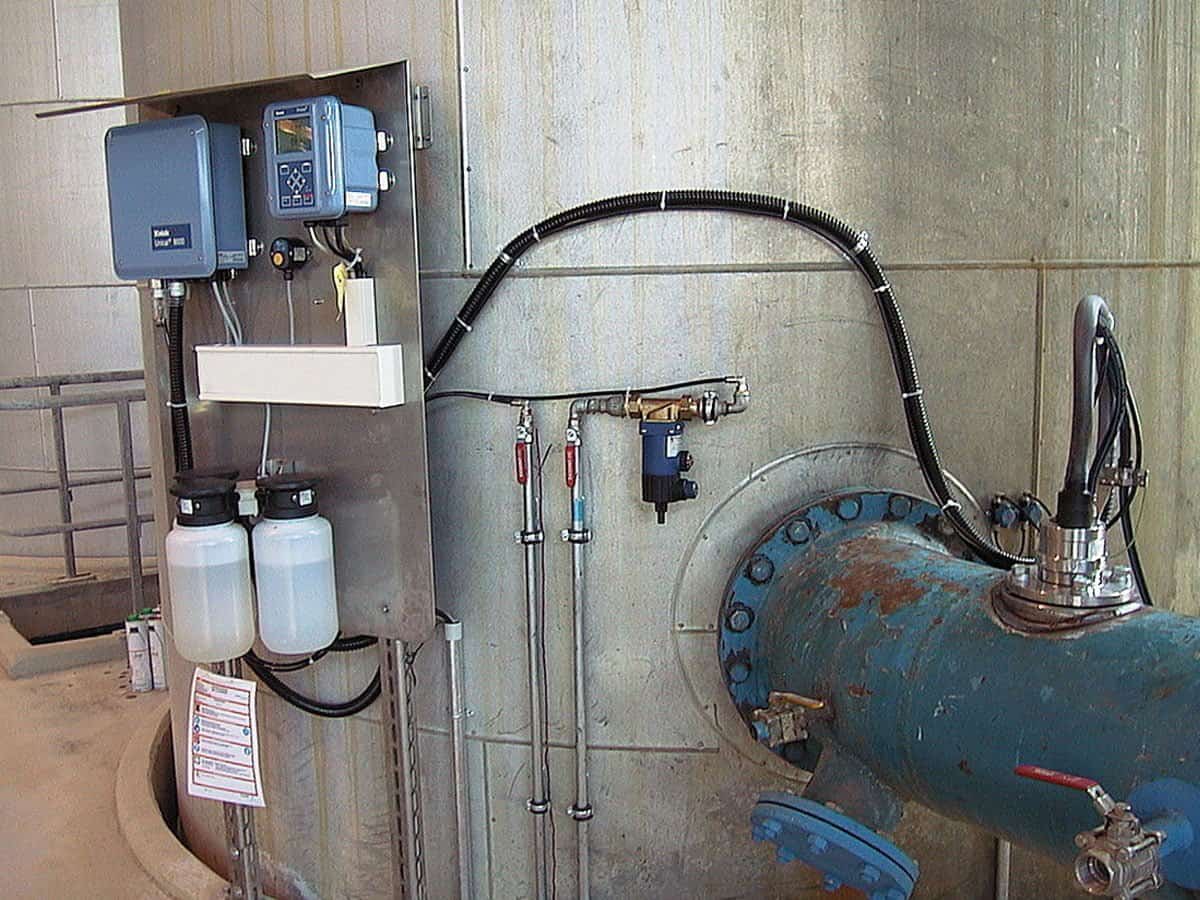

Sensor Contamination in Online Monitoring: Reducing the risk of junction blockage

As a rule, groundwater is characterized by low levels of contamination, but depending on regional circumstances, raw water is gained from surface water and precipitation collected in sewers. To avoid shortened service lives and maintenance intervals, which would require frequent process interruptions, the pH and ORP sensors used for online raw water measurement must withstand heavy contamination. They must also be designed to prevent junction blockage, even at high levels of impurity.

The Memosens SE554 sensor was developed for pH measurement in contaminated, acidic, or alkaline media. As a particularly economical solution, SE554 is also available in a variant with platinum electrodes for simultaneous pH and ORP measurement.

Two open junctions reduce the risk of blockage or contamination to a minimum. Measurement interference that can cause diffusion potential at the junction is reduced by the high potassium chloride content and its special distribution in the polymer of the reference electrode.

Due to their high stability and accuracy and very low maintenance requirements (it is not necessary to refill the electrolyte), using the SE554 sensor contributes to a significant reduction in total operating costs. The SE564 ORP sensor was also developed for use in highly contaminated media with a tendency to form deposits. With both SE554 and SE564, a modern temperature- and pressure-resistant polymer electrolyte ensures measurement with long-term stability and eliminates the need to use conventional ceramic junctions. Instead, the contact between the reference system and process medium is also established here via a double open junction that reliably prevents blockages for measurement in wastewater that contains solid impurities.

Memosens Enables Fast Sensor Replacement and Simple On-Site Troubleshooting

Regular sensor replacement with pre-calibrated Memosens replacement sensors can even be carried out in a few minutes under difficult ambient conditions. After being plugged in, replacement sensors automatically transmit the calibration and sensor data saved in the sensor electronics to the transmitter so that measurement can be continued without significant interruption. Further, the mobile industrial transmitters in the Portavo series enable simple and fast on-site sensor diagnosis in case of measuring loop problems. Simple problems can often be solved by sensor cleaning or re-calibration with Portavo. In this way, it is possible to avoid the prophylactic replacement of sensors and subsequent troubleshooting in the laboratory.

Reliable Measured Value Transmission Range in Wet Environments

Due to the inductive transmission of sensor values and supply voltage in the plug-in connections, using Memosens sensors also avoids interference in measured value transmission in wet environments. Even with sensor cable lengths of up to 100 meters, measured values are accurately transmitted because they are digitized and are therefore not subject to the attenuation that affects analog signals. These transmitters can be mounted in protected environments far away from the measuring loop.

Return on Investment

- The design features of the SE554 and SE564 pH or ORP sensors ensure long service life – even in highly contaminated media.

- Thanks to minimized maintenance effort and extended replacement cycles, using Memosens sensors reduces measuring loop costs.

- Rapid sensor replacement with pre-calibrated Memosens sensors reduces downtime, avoids complicated on-site calibration, and in turn, prevents measured value distortion and subsequent errors. The Portavo 908 Multi mobile industrial transmitter enables the easy acquisition of calibration and sensor data at remote measuring loops.