PROCESS ANALYTICS

Quality Control for Raw Milk Delivery

Quality Control for Raw Milk Delivery

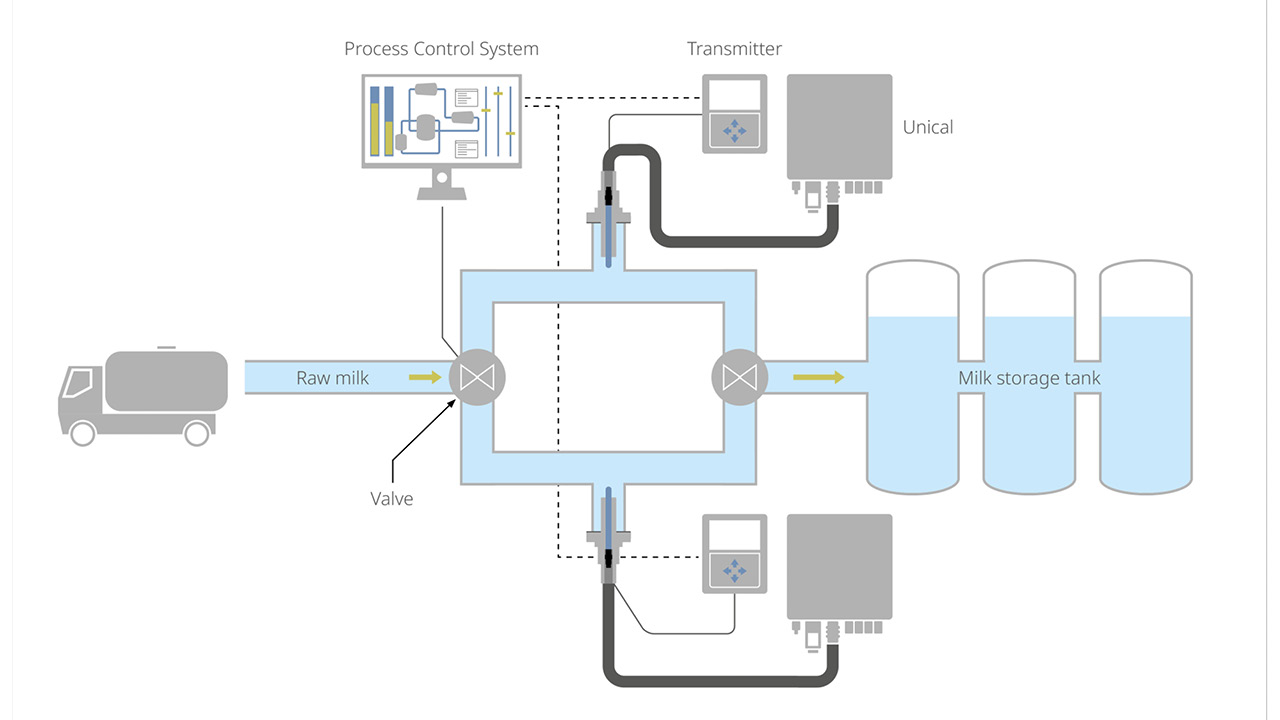

Dairies are supplied with raw milk 24/7. Such high-quality standards are placed on raw milk that online monitoring of the truck unloading operation is necessary. If raw milk of an inferior quality (sour milk) is filled into storage tanks, the entire milk stock is spoiled.

Key Facts About the Application

Sector

Dairy

Application

Online monitoring of the unloading operation

Measuring Parameter

pH value

Main Requirements

Online measurement with automated sensor cleaning and calibration for 24/7 availability

Alerts/alarms in case of failure such that pumping the raw milk into storage tanks can be stopped immediately.

Fulfilling all hygienic requirements like CIP and SIP

Measurement in Raw Milk

Description of application

The quality of raw milk has a critical effect on the quality of milk products. Fresh milk has a pH value between 6.5 and 6.7. The lactic acid bacteria in the milk convert lactose to lactic acid, which is primarily dependent on the temperature. If the milk is sour, the pH value is lower and as of a pH value of 4.5, the milk curdles. Therefore, pH value measurement is ideal for quality control directly upon delivery.

Requirement of the application

When milk is delivered to the dairy, a pH measurement is essential in order to prevent the contamination of an entire tank. As with all applications in the food industry, the requirements are particularly rigorous: Alongside accurate pH measurement, the sensors must be suitable for the usual CIP and SIP processes. In these processes, the closed system is cleaned and sterilized by passing cleaning and rinsing solutions and superheated steam through it.

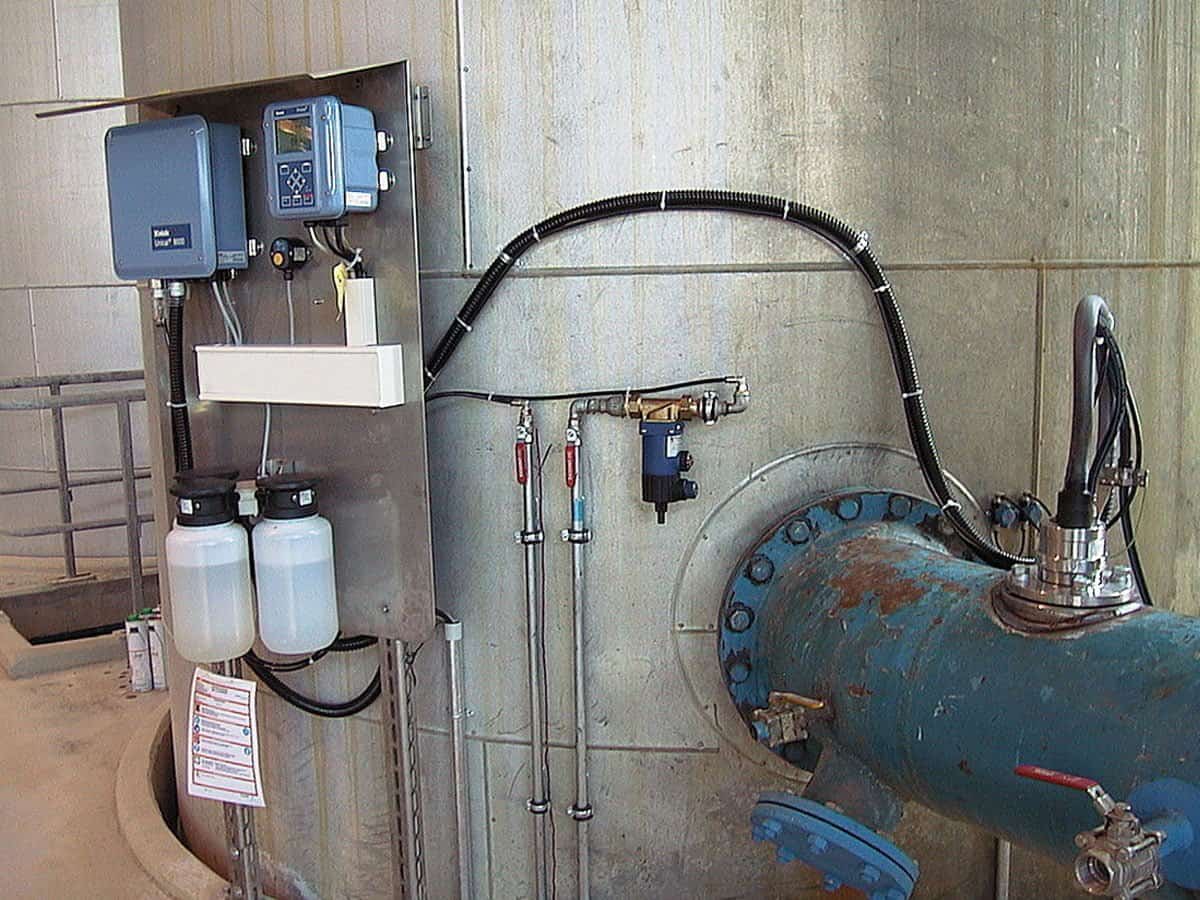

Why Knick?

With high-quality pH sensors and the appropriate process analysis system, raw milk quality can be verified directly upon unloading. Connection to higher-level systems enables it to immediately stop the unloading operation if the pH value is too low. This effectively avoids contaminating the entire tank. With the automated cleaning and calibration system and a retractable fitting with a sensor fitting, the time-consuming removal and replacement of the sensors are no longer necessary. This results in higher availability and a lower personnel requirement for maintenance.

Associated Products

Associated Industries and Applications

Knick offers a solution to extend the life of pH sensors that are susceptible to wear, especially with difficult media: cCare ensures accurate measured values through fully automatic cleaning and calibration of pH sensors while reducing maintenance and material costs.