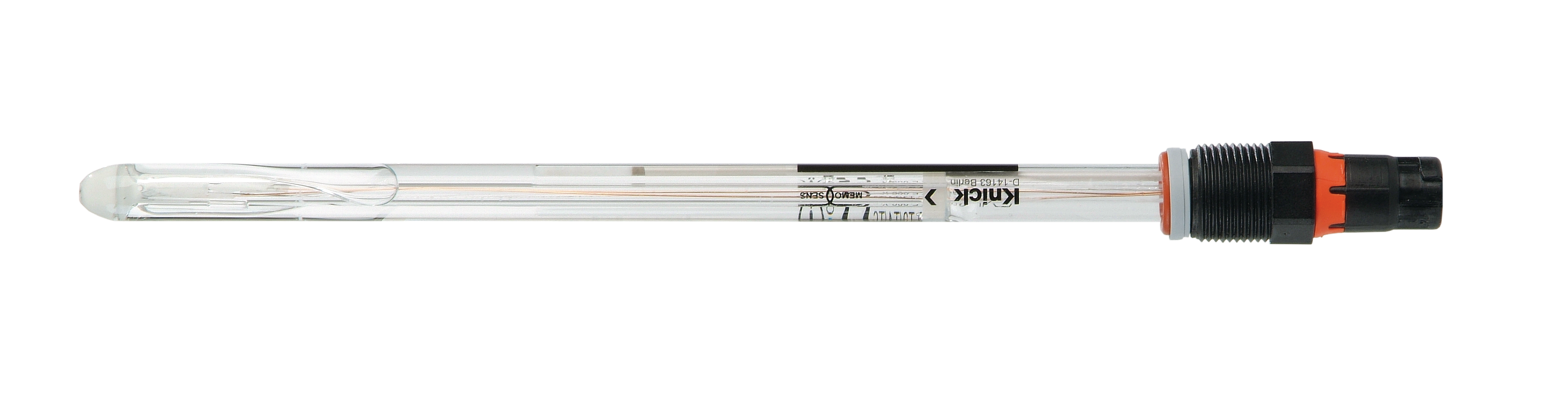

SE564 ORP Sensor | Coax (S8) | 120 mm | Ex | For highly contaminated media with pressure fluctuations

Product number:

SE564X/1-NS8N

Description

SE564 ORP Sensor | Coax (S8) | 120 mm | Ex | For highly contaminated media with pressure fluctuations

Heavy duty ORP sensor providing high reliability and precision.

- polymer electrolyte

- 2-hole junction – no blocking

- for industrial sewages

- Suitable for solvent-containing processes

Heavy duty ORP sensor designed for highly contaminated media with pressure fluctuations. The state-of-the-art polymer electrolyte of the reference system provides good long-term stability.

The 2-hole junction prevents blocking also in waste water containing solid impurities.

Applications

Industrial applications, dyes, precipitation reactions, polluted media

We look forward to hearing from you!

Contact Us

| Connector: | DIN Koax (S8) |

|---|---|

| Explosion protection: | Yes |

| Length: | 120 mm |

| Process Connection: | PG 13.5 |

| Measuring Range: | ± 1500 mV |

| Temperature: | 0 … 130 °C |

| Pressure, relative: | 0 … 10 bar |

| Temperature Detector: | NTC 30 kΩ |

| Junction: | Hole (2x) |

| Reference System: | Ag/AgCl, polymer electrolyte |

| Material of measuring electrode: | Platinum |