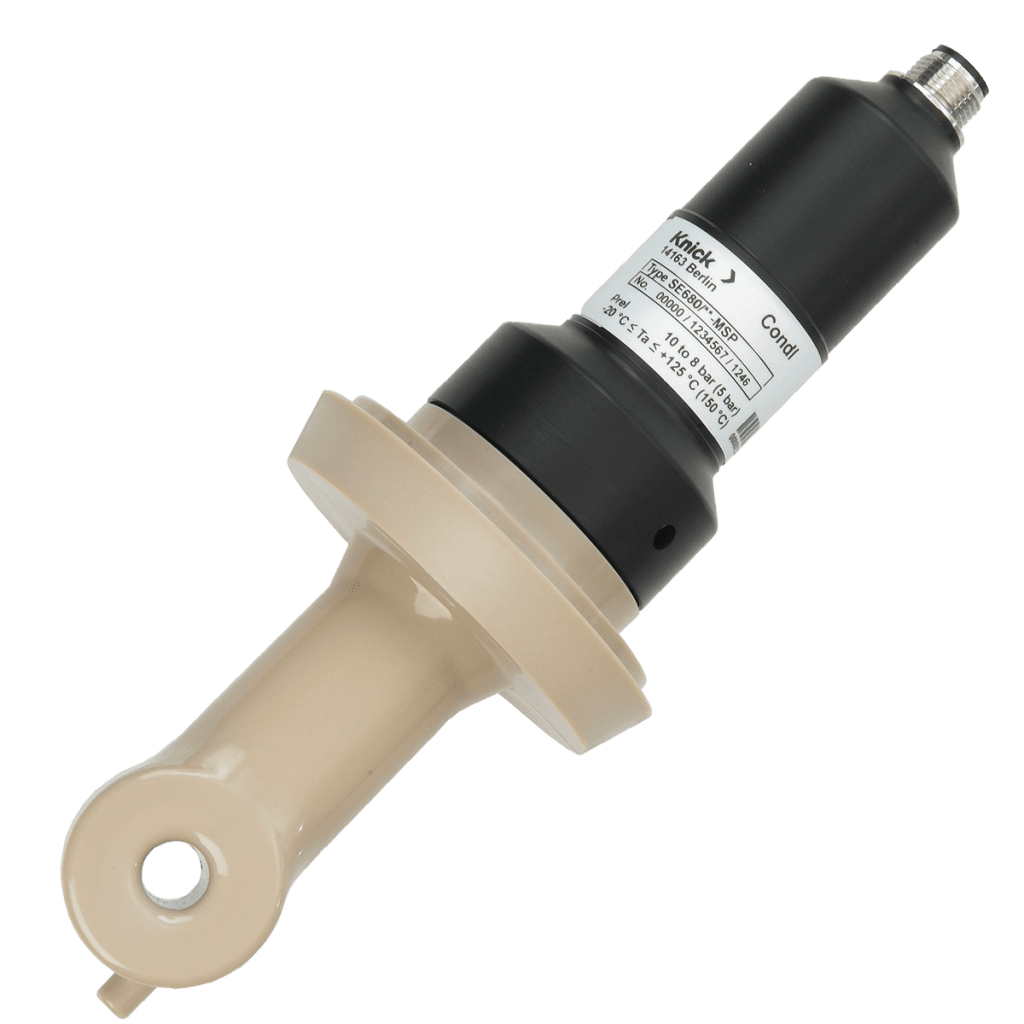

SE655 Toroidal Conductivity Sensor | Memosens | 7 m Fixed cable | Ex | PEEK | High chemical resistance

Description

Universal and precise conductivity sensor with high chemical resistance. Digital with Memosens protocol.

- Process-wetted material: PEEK

- Sturdy design

- Resistant to contamination and fouling

- Range of six decades

- Steam sterilizable and CIP capable

- Inductive measuring principle, full galvanic isolation of sensor coils from process medium

- Digital with Memosens protocol

- Also for hazardous areas

The SE655N digital toroidal conductivity sensor is a sturdy and corrosion-resistant sensor that, thanks to its high chemical resistance, is particularly suitable for applications in the chemical industry.

A combination of a large sensor opening and dirt-repellent material prevents blockages and deposits in media with a high pollution degree. The inductive measuring principle enables full galvanic isolation of the measurement from the medium.

The sensor is an all-rounder, suitable for a multitude of applications with a range covering six decades. Equipped with Memosens protocol as a digital version, it offers considerable process and data security, and ensures reliable data recording. Also for hazardous areas (SE655X-GEFTT0AM).

Applications

Concentration measurement of acids and bases, online quality monitoring of chemical products in tanks and pipes, phase separation of product mixtures, paper manufacturing (high fiber concentration), heavily soiled media and wastewater, fouling and oil-contaminated media, brine, regeneration of ion exchangers.

We look forward to hearing from you!

Contact Us

| Measurement Parameter: | Conductivity (inductive) |

|---|---|

| Measurement error: | ± (0.005 mS/cm + 0.5 % meas. value) | (- 20 ... 100 °C), ± (0.010 mS/cm + 0.5 % meas. value) | (> 100 °C) |

| Explosion protection: | Yes |

| Process Connection: | G 3/4" (36-mm nut and FKM (Viton) gasket included in shipment) |

| Measuring Range: | 0 ... 2,000 mS/cm |

| Temperature Detector: | Pt1000 (Class A in accordance with IEC 60751) |

| Measuring principle: | Inductive |

| Relative process pressure: | 0 ... 20 bar (see pressure/temperature diagram) |

| Material: | Cellule: PEEK; Joint: FKM (Viton) |

| Fixed cables with ferrules: | 7 m |

| Protection: | IP 68 (sensor mounted, with original gasket / EN 60529) |

| Temperature response time t90: | Approx. 7 min |

| Ambient temperature: | –20 ... +60 °C |

| Storage temperature: | –20 ... 80 °C |

| Cell factor: | 1.98/cm (≥30 mm wall clearance) |

| Signal Transmission: | Memosens Protocol |

| Resolution: | 0.002 μS/cm |