Raccourcis

Tags

Derniers articles

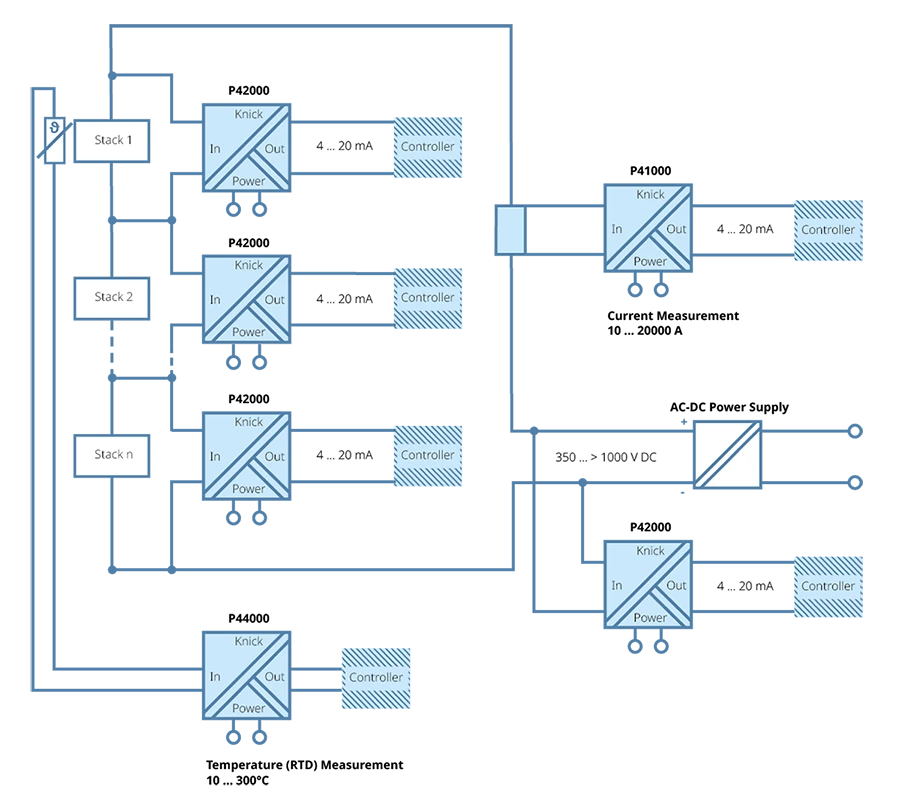

Stack and String Voltage Measurement in Electrolyzers and Fuel Cells

Green hydrogen plays a key role in the energy transition. As a zero-carbon fuel with high energy density, hydrogen will be the best option in the future for transporting renewable energy or storing it remotely. The output of electrolyzers that produce hydrogen with electricity from wind farms and solar power stations is constantly growing. In order to guarantee the maximum efficiency and process reliability of these systems, continuous condition monitoring of the electrolysis cells, which are integrated in large quantities, is necessary. To achieve this, failsafe transducers that safely isolate high potentials and measure direct currents up to (currently) 1500 V with high precision are required.

Increasingly High Power

Depending on the manufacturer, in modern electrolyzers, up to several hundred electrolysis cells are wired into stacks that can be replaced as complete units in case of failure or maintenance. Since individual electrolysis cells require average operating voltages between 1 and 4 V DC, stack voltages can be several 100 V DC. Further, in larger-scale electrolyzers, multiple stacks can be combined into individually controllable strings with significantly higher total voltages. The current trend is to string voltages up to 1500 V DC. Today, electrolyzers with electrical power consumption in the two-digit megawatt range are in operation.

Fuel cells, on the other hand, support the efficient, clean conversion of hydrogen into electricity. They use a process that is the inverse of the electrolyzer process: It generates electricity through the reaction of hydrogen and oxygen. Like electrolyzers, fuel cells consist of cells and stacks that are wired to create high voltage strings.

Voltage Monitoring for Purposes of Diagnostics

In order to detect defects and signs of wear on electrolysis or fuel cells, it is necessary to continuously and accurately measure stack and string voltages. Occasionally, the voltages at sub-units of stacks are also measured. In these cases, the measured voltages are lower, but high potential differences occur due to the wiring. Accordingly, the transducers must be highly isolated. It is also necessary to monitor currents and temperatures. To do this, the transducers used must not only meet high standards of precision and robust isolation, but also be failsafe and maintenance-free. Since the electrolyzers are housed in containers next to wind farms or photovoltaic power stations, which are typically set up in remote locations, system availability significantly depends on the reliability of the measuring technology.

Perfect Solutions: High Voltage Transducers in the P40000 Series

With their extreme long-term stability, the high voltage transducers in the P40000 series offer optimal solutions for voltage, current, and temperature measurement in electrolyzers. The transducers guarantee a basic isolation up to 3600 V and reinforced isolation up to 1800 V. Due to the conservative and fully encapsulated electronics design, they achieve an MTBF of 2165 years (based on field data). They also feature outstanding transmission properties with a gain error of < 0.3 % of the measured value and, like all products from Knick, do not require recalibration over their entire service life. Further, the compact housing for DIN rail mounting simplifies their integration into retrofit applications as well.

Latest Posts

Process Analytics

Pharma, Sensor, Conductivity

Interface Technology

Hydrogen

Interface Technology

Interface Technology

Exhibition, InnoTrans

Process Analytics

Achema

Produits assignés

P44000

Articles connexes

sept. 2024

Interface Technology

Hydrogen

Stack and String Voltage Measurement in Electrolyzers and Fuel Cells

sept. 2024

Interface Technology

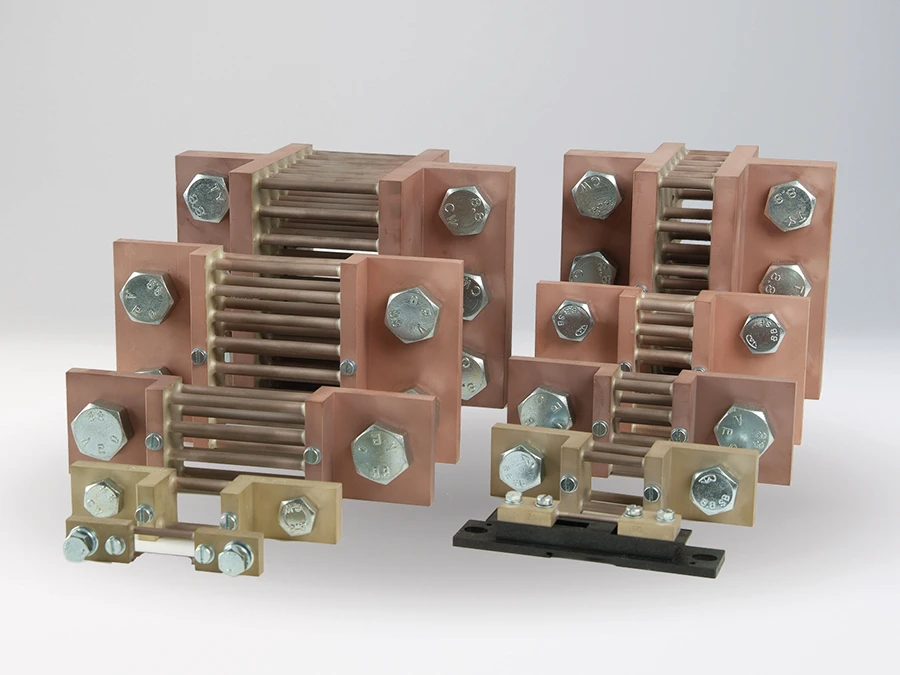

Des nouvelles résistances shunt de 30 mV pour les convertisseurs de mesure de Knick

sept. 2024

Interface Technology

Exhibition, InnoTrans