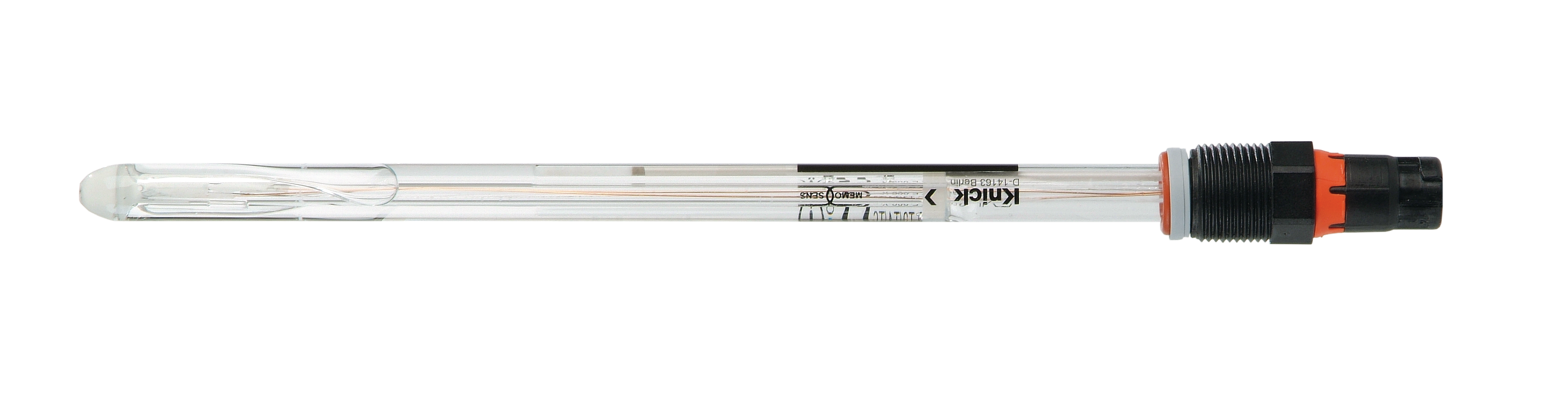

SE565 Sensore Redox | Memosens | 225 mm | Ex | Per processi igienici e applicazioni sterili

Description

Sensore Redox per processi igienici e applicazioni sterili.

- Perfetto isolamento galvanico grazie alla tecnologia Memosens

- Nessuna influenza dell’umidità sul connettore

- Trasmissione dati digitale

- Diagnostica del sensore integrata

- Moderno elettrolita a gel

- Sonda di temperatura integrata

- Diaframma in ceramica

- Per applicazioni igieniche e sterili

- Per fluidi fortemente contaminati

- Per fluidi contenenti solfuri

- Per fluidi contenenti proteine

- Adatto per processi contenenti solventi

I sensori Redox SE565 richiedono una manutenzione ridotta. Il sistema di riferimento in pressione con elettrolita a gel è collegato al fluido di misurazione tramite un diaframma in ceramica. L’elettrodo di misura è in platino.

I sensori SE565 sono progettati per misurare contemporaneamente il valore Redox e la temperatura nei processi industriali.

Sono adatti per la sterilizzazione a vapore e dispongono di un sistema di riferimento sviluppato per l’impiego con prodotti alimentari e farmaceutici.

Applicazioni

Applicazioni igieniche e sterili, industria alimentare e farmaceutica, biotecnologie

Non vediamo l'ora di ascoltarvi!

Contatto

| Campo di misura : | ± 1500 mV |

|---|---|

| Collegamento di processo: | PG 13,5 |

| Connettore: | Memosens |

| Diaframma: | Ceramica (1x) |

| Lunghezza: | 225 mm |

| Material of measuring electrode: | Platino |

| Parametro di misurazione: | Redox |

| Pressione, relativa: | -1 … 6 bar |

| Protezione contro le esplosioni: | Sì |

| Sistema di riferimento: | Ag/AgCl, elettrolita in gel con cuscinetto di pressione |

| Sonda di temperatura: | NTC 30 kΩ |

| Temperatura: | 0 … 135 °C |