Automatic pH measurement with cCare

You have just taken a step into the future. As you know better than anyone, digital pH measurement is an essential aspect of your industrial processes where maintaining accurate pH levels is critical to product quality, process efficiency and regulatory compliance.

The introduction of digital pH meters and sensors has already revolutionized the way pH can be monitored and controlled. Nevertheless, challenges remain, such as chemically very aggressive media, which shorten the service life of the sensors, or the need to avoid contamination in order to obtain continuous reliable measured values. Thorough cleaning and calibration of the sensors is therefore essential. This costs time and resources.

With our cCare sensor maintenance system, we offer you a solution for the complete automation of your pH measuring points.

Welcome to the world of fully automatic digital pH measurement from Knick!

Automate your measuring point! We will be happy to advise you.

Contact UscCare - System for fully automatic sensor maintenance

Our pioneering solution cCare revolutionizes the care of pH sensors. The fully automatic cleaning and calibration of sensors with cCare brings many advantages for industrial pH measurement: highly accurate measured values, seamless data management and therefore maximum safety. In addition, you reduce your maintenance costs and thus increase the efficiency of your production systems.

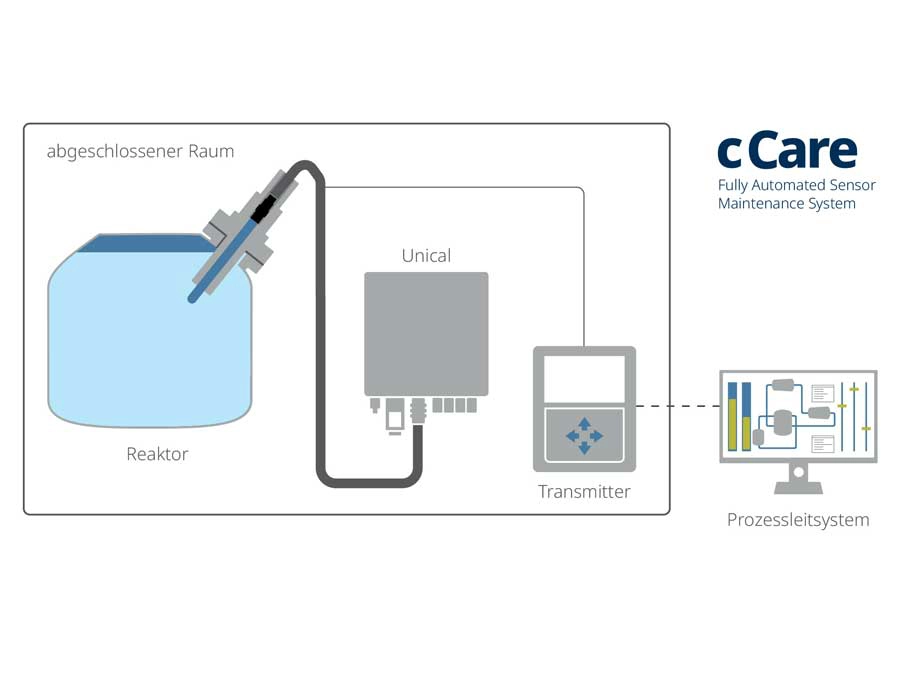

pH measuring points equipped with cCare reliably supply data directly to your process control system, promote digitalization and optimize processes and product quality. cCare not only stands for efficiency in the process industry, but also for safety for people and the environment.

Maintenance cost savings

The measuring accuracy of pH sensors is relevant in order to avoid production interruptions or quality defects. However, conventional maintenance of pH sensors is labor- and material-intensive, especially in large systems or where measurement requirements are high. Daily cleaning operations are often necessary in the event of media-related electrode wear or diaphragm contamination. cCare almost completely eliminates the manual effort at the measuring point and thus reduces costs.

Precise measurement data and digitalization to increase efficiency

cCare standardizes processes (sensor cleaning, calibration, measurement). This leads to highly precise measured values and a better understanding of the process sequences. Digital communication from the sensor to the process control system enables process steps, such as the addition of raw materials or reaction times, to be optimized, thereby significantly increasing the efficiency of your systems. Digital sensor management allows maintenance work to be planned in advance, thus avoiding downtimes.

Adaptable all-rounder system

The advantages of cCare are manifold. The customers' requirements too. Thanks to the unique modularity of the components, the system can be tailored to your needs. Consisting of an electro-pneumatic control unit (Unical 9000), an interchangeable fitting (Sensogate or Ceramat), a Memosens pH sensor and a Protos transmitter, the optimum setup can be found from over 1000 configurations. This adaptability guarantees the efficiency of cCare.

Process safety incl. Ex-zone accreditation

Many measuring points are located in places that are difficult for staff to access. Be it due to toxic media, high purity or simply due to long distances. As a unique sensor maintenance system, cCare and all its components are approved for use in Ex zone 1. By using pre-calibrated Memosens sensors, cCare guarantees maximum reliability, regardless of the ambient conditions. Knick retractable fittings ensure safe process separation, even while the process is running, effectively and reliably preventing the release of hazardous substances for people and the environment.

Video of the presentation of the cCare Pharma System at ACHEMA 2024

Is manual pH calibration a game of chance?

Unical 9000 - Control unit

The Unical 9000 control unit is characterized by a uniform housing concept across all devices and offers a modular design that can be adapted to practically any measuring task.

Highlights:

- Easy installation and retrofitting

- Tidy hose routing

- Optional hygienic versions (stainless steel, polished, FDA materials, etc.) Corrosion-resistant steel ensures flexibility and versatility of use

- Optional Ex Zone 1 certified

Pneumatic retractable fitting

Both fittings from the Ceramat and SensoGate series can be used. These retractable fittings are particularly impressive due to the following

Highlights:

- Available in a wide range of materials, process ports and immersion lengths

- Unique probe cleaning

- Patented closing concept, primary sealing without O-rings

- Also suitable for optical probes

Protos II - Transmitter

The heart of the system - the central programming and operating unit. Uncomplicated navigation and configuration and therefore flexibly adaptable to your process requirements. Analog and digital communication protocols make connection to your process control system child's play. Optimally designed for use with Memosens probes.

Media adapter with containers and metering pumps

Optionally, 1-4 cleaning and calibration solution containers with wear-resistant pumps can be used. The capacity of 3.5 l buffer solution per container is sufficient for up to 140 calibrations. An additional cleaning or flushing liquid can also be added via the external valve in the control unit.

Service switch

Thanks to the central safety switch, the sensor can be immediately retracted into the fitting. With warning signal function and active feedback on the current sensor position for a quick response.

Digital pH sensors for the automated measuring point

The past was characterized by metallic, analog contacts between sensor and cable. Due to moisture, corrosion or cable breaks, problems with measured value transmission and accuracy were the order of the day. In addition, the sensors often had a shortened service life.

Memosens sensors solve these challenges with their inductive plug connection, which is insensitive to interference even with cable lengths of up to 100 meters.

Digital measured values are transmitted contactlessly from the sensor to the transmitter; all data relevant to the measured value is stored and processed in the sensor head. The digital data is exchanged bidirectionally between the sensor and transmitter and is not subject to fluctuations. The storage of calibration, sensor and process data in the digital sensor head offers many advantages.

- Advantage 1: The Memosens connector system guarantees absolute tightness and insensitivity to dirt, corrosion and interference potential through contactless inductive transmission.

- Advantage 2: Memosens enables the pre-calibration of sensors in the laboratory, increases measurement accuracy and extends the service life of sensors by up to 40%.

- Advantage 3: The intelligent Memosens electronics continuously store the status of the sensor, which enables precise diagnostics and ensures greater safety, efficiency and reliability.

- Advantage 4: Detailed sensor data can be transmitted to your process control system via a bus protocol. Digital communication thus ensures seamless data recording.

Possible uses / applications

cCare is used in various production processes such as biotechnology, ChemPharma or chemistry. What all applications have in common are the highest demands on process analysis. See for yourself how cCare can optimize your process:

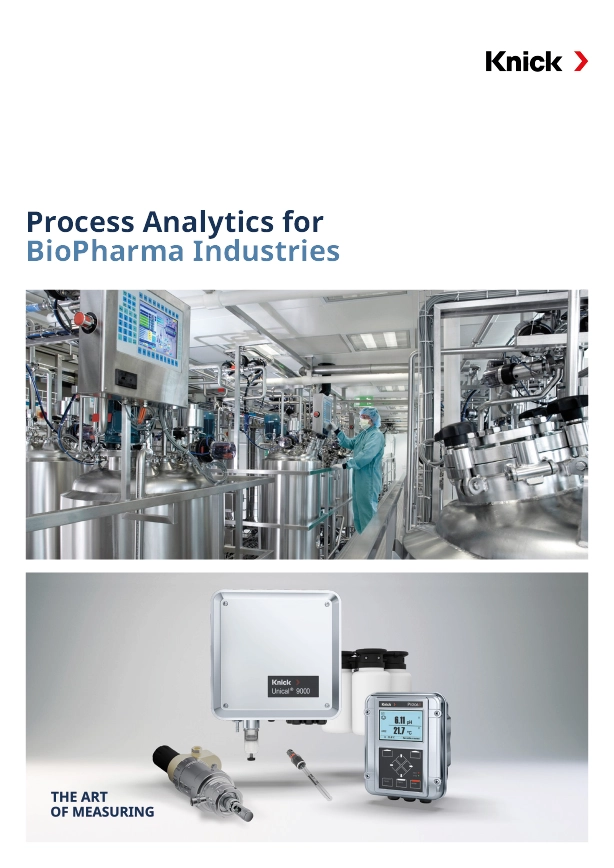

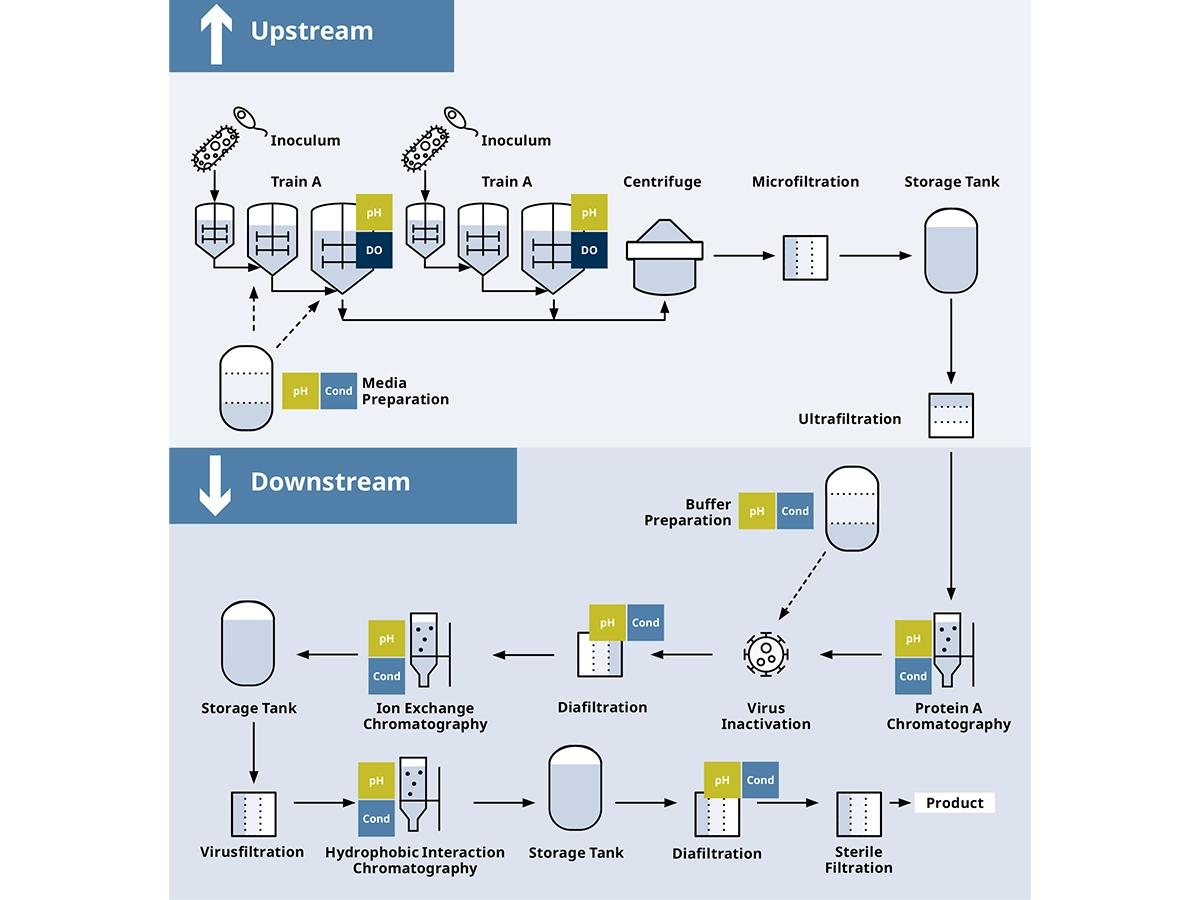

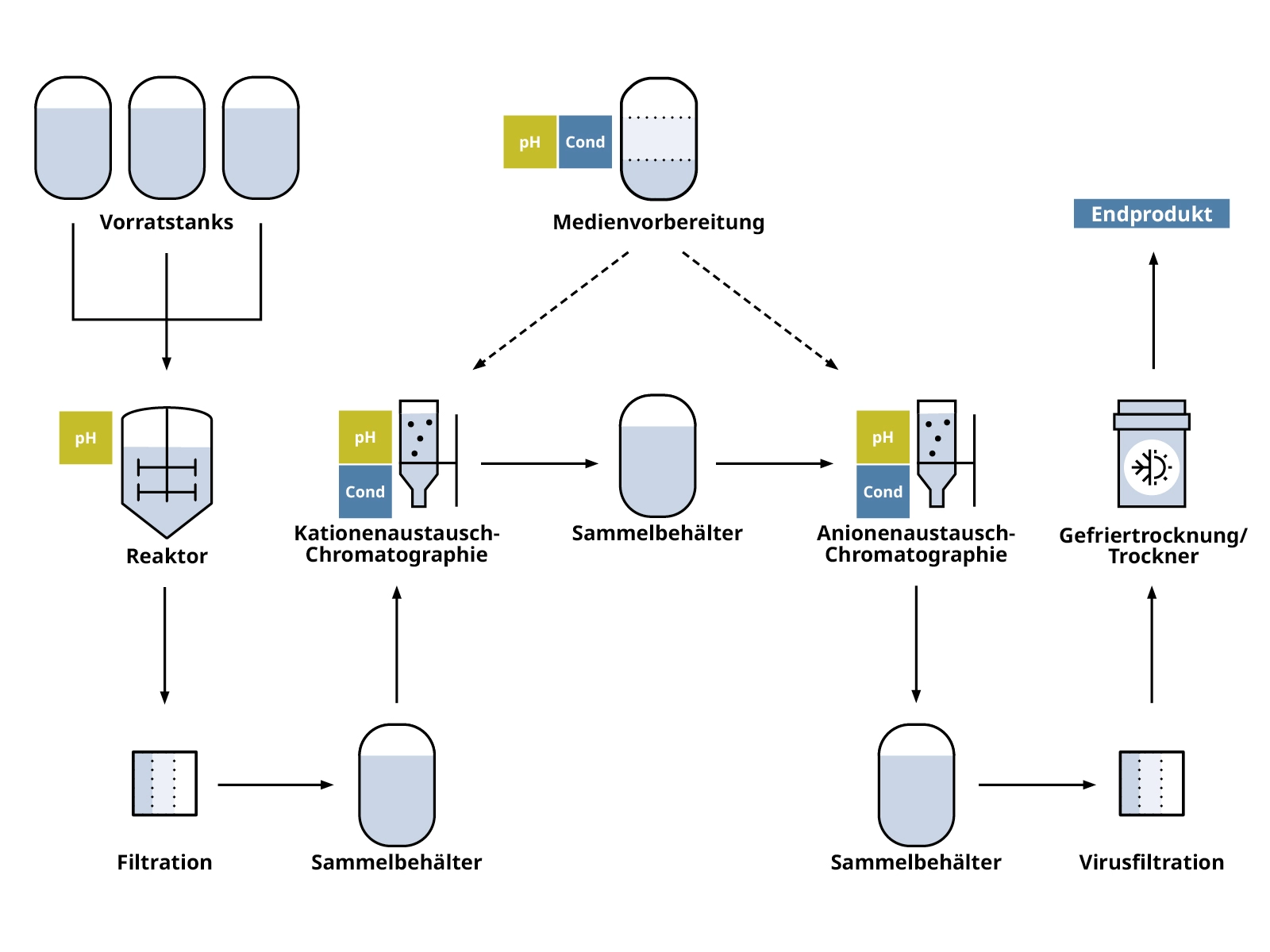

Automation of pH measuring points in the BioPharma sector

Each step of the biopharmaceutical process, both upstream and downstream, is important and requires specific measurement technology to control the process parameters. Automating pH measurement with cCare helps to maximize yield and avoid process deviations or batch losses.

Do you have questions about automating your measuring points or cCare? We will be happy to advise you.

Knick Switzerland

Phone: +41 62 501 00 26

Not your country? Find your lokal partner.

Automatic pH measurement in the ChemPharma process

Wet-chemical active ingredient production is constantly changing. In particular, the requirements of the supervisory authorities for seamless data management and the shortage of specialists can pose challenges. The digitalization and automation of process analytics provides a remedy here.

Do you have questions about automating your measuring points or cCare? We will be happy to advise you.

Knick Switzerland

Phone: +41 62 501 00 26

Not your country? Find your lokal partner.

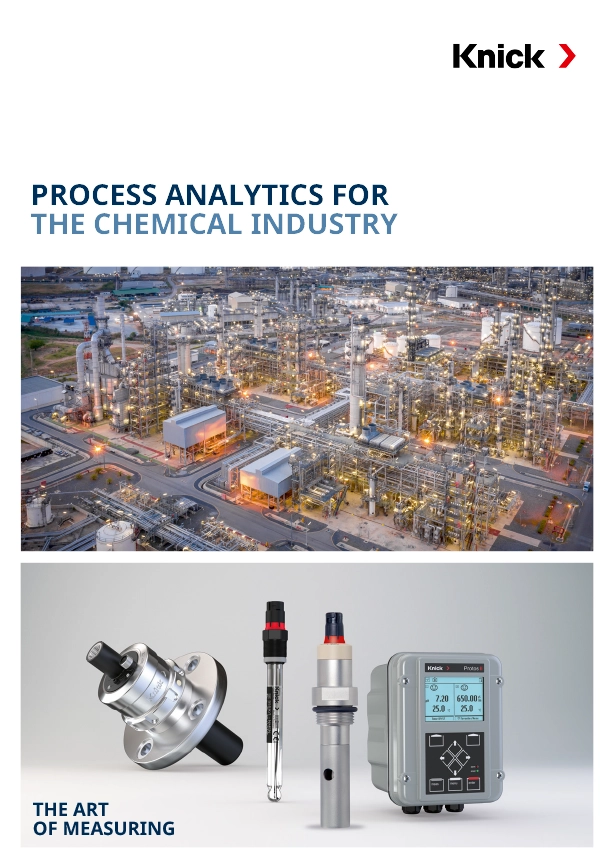

Automating pH measurement in the chemical industry

Difficult process conditions and continuous processes place high demands on measuring points and personnel in the chemical industry. The automation of pH measuring points increases the service life of the systems and improves safety for people and the environment.

Do you have questions about automating your measuring points or cCare? We will be happy to advise you.

Knick Switzerland

Phone: +41 62 501 00 26

Not your country? Find your lokal partner.

Your return on investment

- Automated systems optimize your process management and directly influence operating costs, process time, safety and user safety.

- With individual diagnostic and sensor maintenance settings, they minimize downtimes and increase process yield.

- Before automation, manual sensor maintenance required a considerable amount of time, especially in hazardous areas. Automating the removal, cleaning and calibration of sensors drastically reduces these efforts.

- Standardized calibration procedures enable more precise measurements, allowing processes to be run more accurately and process yields to be increased.

- If pH probes are not required in the process, they can be automatically stored in regeneration solution. This leads to better performance and a longer service life.

We will be happy to quantify the economic benefits for you with our ROI calculator. Please use the form to contact us.

Automate your measuring point! We will be happy to advise you.

Contact Us