Transformers have long been considered important components within electrical systems. When a need arises to step voltage in a circuit either up or down for purposes of power transmission or distribution, there is no doubt that these devices are essential.

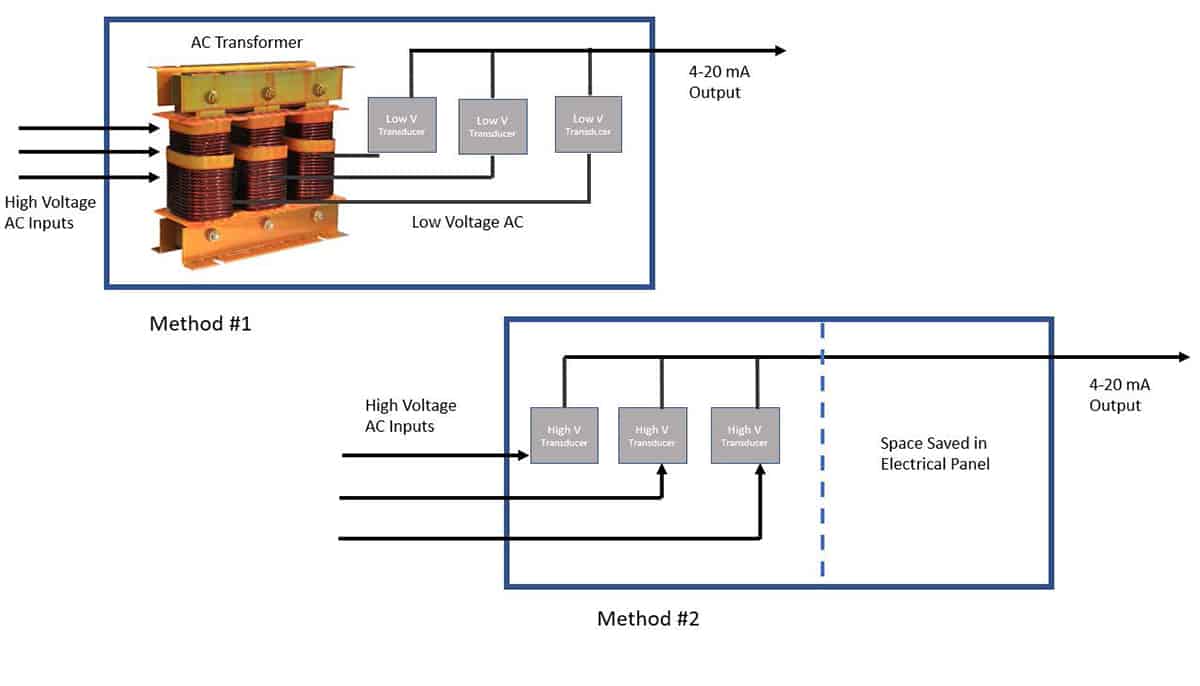

Transformers are also used to bring voltages down to a lower level for purposes of measurement. Used this way, they are often referred to as instrument transformers. These electrical readings are used for control, safety and/or data collection. The instrument transformer is paired with a secondary device, called an AC/DC transducer, which takes in these lower voltages as input signals and converts them to effective or RMS values, (i.e. standard DC signals that are more easily read by control and collection systems.) Examples of standard DC signals are 4-20 mA or 0-10 VDC.

Although this method of measuring system voltage has worked successfully in many installations, there are reasons to consider an alternative approach, as additional value may be introduced.

Recently, transducers have been developed that can directly process voltages originally considered to be too high to measure and isolate without first passing them through an instrument transformer. Where previously, voltage levels of AC/DC transducers topped out at 400 or 690 V, devices are now available that can directly handle AC and DC voltages of more than 3000 V, in form factors that are much smaller than what would be required with transformer usage. Even true root mean square (TRMS) measurements are possible for correct pick-up of distorted signals, where a clean AC sine wave does not exist and therefore cannot be assumed at the output.

The P42000 series, by Knick Interface, is an example of such a device. It can directly process AC and DC inputs up to 3600 V, while giving the user the option of selecting any one of a number of standard DC outputs. And with AC input signals, the P42000 series provides TRMS processing, bringing accuracy with measurement of any input signal, regardless of whether or not it is distorted.

The reduction in size, seen with high-voltage transducers like the Knick Interface P42000, offer a handful of benefits, most of which can ultimately be tied back to cost savings. For instance, components like these are typically mounted in an electrical panel or enclosure. The real estate needed is, of course, proportional to the size and number of components needed to be housed within the enclosure. The smaller the devices in both size and number, the smaller the enclosure, and the lower the cost. This cost savings is reflected in the material of the panel itself, but also shows with the overall footprint of the system and in the minimization of the weight. Typically, there is a substantial weight and size difference between transducers and the transformers that they can sometimes replace in voltage measurement applications.

This cost savings is even more substantial and pronounced in applications where a secondary transducer was to be used anyway to generate a standard output signal. (See Figure 1.) In these cases, not only are all the cost saving benefits versus a transformer seen in a comparison versus a higher voltage transducer, but additional cost is saved by elimination of the secondary transducer. This cost savings is seen in direct transducer costs, panel space and weight, and with eliminating the need for additional wiring.

In addition to cost savings, there is an additional benefit often seen when comparing a high-voltage transducer against a system employing a transformer with secondary transducer, and that is with accuracy of measurement. With a high-voltage transducer, there is no effect seen with additive errors, as a single component is producing the measurement. This is not the case with the transformer and transducer combination, as the accuracy is affected by the errors introduced by both devices, as well as the wiring between them. It is of course important to consider a quality high voltage transducer if looking to maximize the accuracy seen with the measured value.

9월 2024

Interface Technology

Hydrogen

9월 2024

Interface Technology

9월 2024

Interface Technology

Exhibition, InnoTrans