Hydrogen is currently in the spotlight as an energy and storage medium. Knick products optimize hydrogen production in the process and in electrolyser operation. How this works was presented by two of our experts at the virtual H2 Forum 2021 at the end of April.

In the future, hydrogen will make an important contribution to a sustainable energy supply. Renewable energies from wind, sun and biogas are often available when they are not needed. Many wind turbines are even shut down when the wind situation is good and they could be operating most efficiently. The problem is oversupply and weak power grids that cannot adequately draw and transport the energy.

Storage technology is needed and batteries have major disadvantages in terms of durability and the components that are not infinitely available and are difficult to recycle. Without storage technology for the “green” energy, there will always be a gap in the energy supply that will have to be filled with climate-damaging fossil fuels. Many experts therefore believe that green hydrogen is the solution, and the German government is promoting the development of hydrogen and fuel cell technologies to stay ahead of the innovation competition.

On 27 and 28 April 2021, a virtual conference for energy suppliers, automotive and industrial companies, technology manufacturers and research institution took place, at which Knick was represented by two conference speakers. The online event brought together decision-makers, experts and solution providers around the future of green hydrogen. Expert presentations and a virtual product exhibition invited discussion and networking. On April 27, 2021, Joachim Baumann, Sales Director Interface Technology talked about current and high voltage measurements on electrolysis cells. On the second day, Dr. Michael Kogej spoke in a pitch about process analysis in hydrogen production.

Eventdetails and Conference Agenda

Electrolysers are independent systems in which hydrogen is produced by electrolysis using direct current. With such systems, renewable energy can be converted into hydrogen directly at the point of generation. Electrolysers consist of stacks (electrolysis cell packages) of a water treatment unit, a gas treatment unit and the power electronics including measurement technology, control and interface management. Ideally, all modules are integrated in a ready-to-connect container and can then be installed directly at wind farms, solar farms or biogas plants.

Precise measurement of system parameters such as current, voltage and temperature directly at the electrolyzes are general requirements for safe operation in the electrolytic production of hydrogen. Regardless of the type of conversion process, the operators place extremely high value on reliability and demand a long service life.

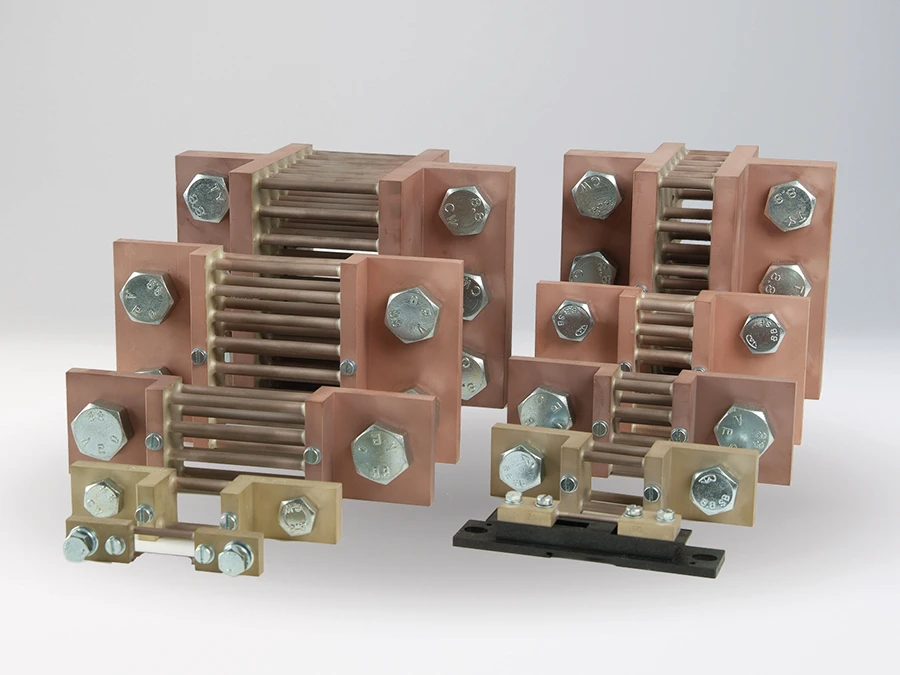

With the Knick ProLine P40000 product range, we offer you solutions with an individual choice of measuring ranges. Extremely high MTBF values of > 2000 years calculated from products in service are proof of the reliability. The isolating amplifiers for current and voltage measurement can be used in systems with up to 2200VDC. Together with P41000 and one MACONIC shunt resistor we can precisely measure current up to 20000A

Knick Interface products are known for

Knick process analytics for hydrogen production

Although process analytics equipment seems to be inappropriate in hydrogen generation, it is nonetheless very important for technical and efficiency reasons.

An indisputable fact is water electrolysis as the main source for hydrogen gas. Actually, most of the generated hydrogen uses fossil sources. By developing and optimizing electrolysis techniques these processes will be more or less obsolete in the near future. The main source for clean and green hydrogen is water. This ubiquitous substance must have a high purity to be used for that purpose.

The measurement system STRATOS MULTI in combination with the conductivity sensor SE605(H) guarantees high quality water.

The STRATOS MULTI monitors the water quality online and directly displays/transfers the measurement value to the control system. Many more benefits are given by this system:

The conductivity sensor SE605(H) is specially designed for conductivity measurements in pure/ultra-pure water. The digital Memosens protocol is implemented inside the sensor head so that precalibrated sensors can be used shortly after installation and connection to the measurement system STRATOS MULTI.

9월 2024

Interface Technology

Hydrogen

9월 2024

Interface Technology

9월 2024

Interface Technology

Exhibition, InnoTrans