Process Water Analytics for Power Stations

Green and renewable energy sources like solar and wind power are making inroads in today’s energy market. Nevertheless, thermal power stations are still the backbone of generating electricity and process steam in many countries and industries.

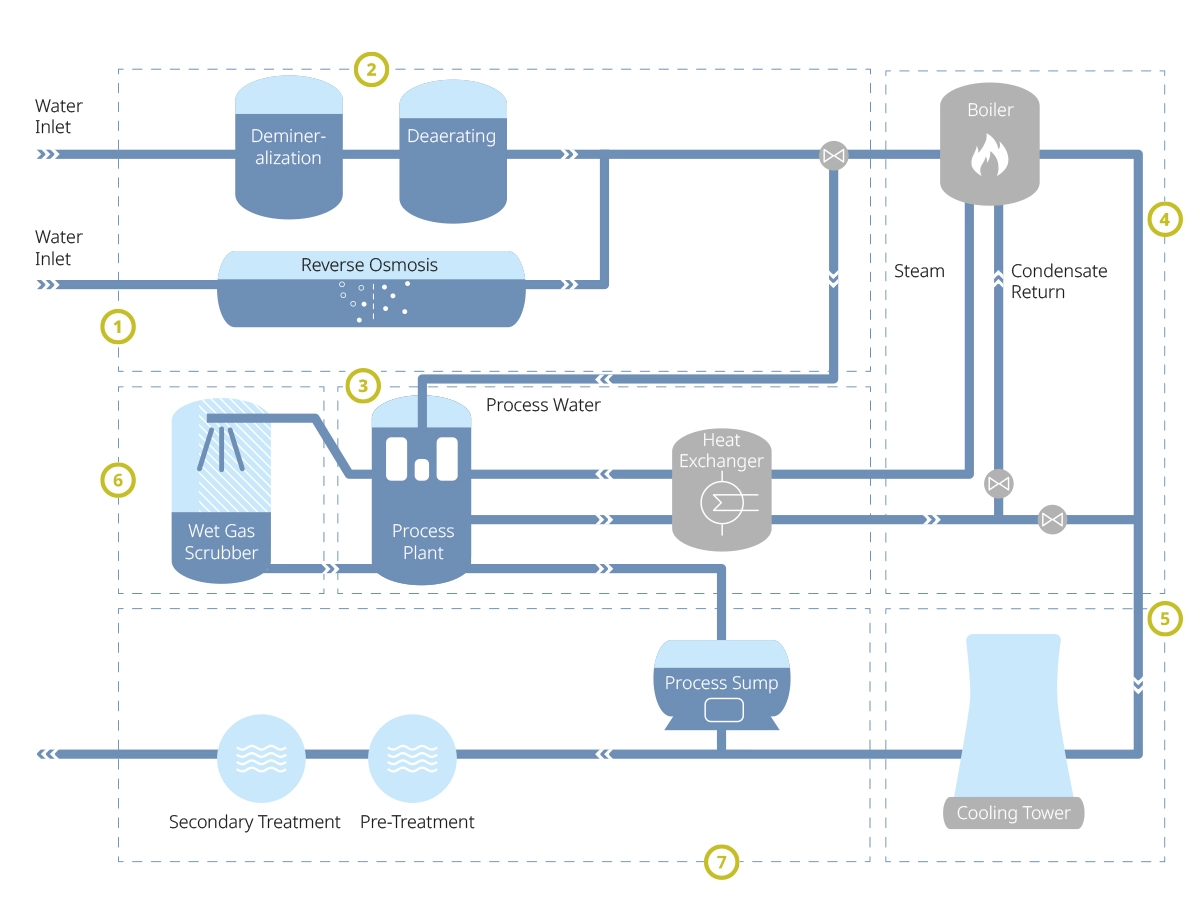

Steam, Cooling, and Condensate: Water for Every Process Step

The energy source for these power stations can be coal, oil, gas, nuclear power, or green energy like biomass and geothermal energy. Thermal power stations work with a thermodynamic cycle in which pure boiler feed water is converted into the steam that drives the turbines for electricity generation. The steam can also directly be used to heat buildings or in industrial processes. Used steam is cooled down and forms liquid condensate. The condensate is transported back to the boiler in order to trigger the thermodynamic cycle again. Alongside the boiler feed water cycle as a core process, a thermal power station requires feed water treatment systems (reverse osmosis, ion exchanger), a cooling water system, a flue gas scrubbing system, and of course, a wastewater monitoring system.

Steam Systems

Flue Gas Scrubbing

Water Cooling Systems

Water & Wastewater

Why Knick?

Thanks to Knick’s many years of experience with process analytics in the energy industry and a wide range of Matching Products like flow-through fittings and compact transducers for DIN rails, as well as multi-purpose use of the same devices, the company is able to adapt simple, inexpensive solutions to the requirements of the measuring loop.

Related Applications

Do you have questions? We are here for you.

Contact us!