PROCESS ANALYTICS

Ion Exchanger Systems

Ion Exchanger Systems

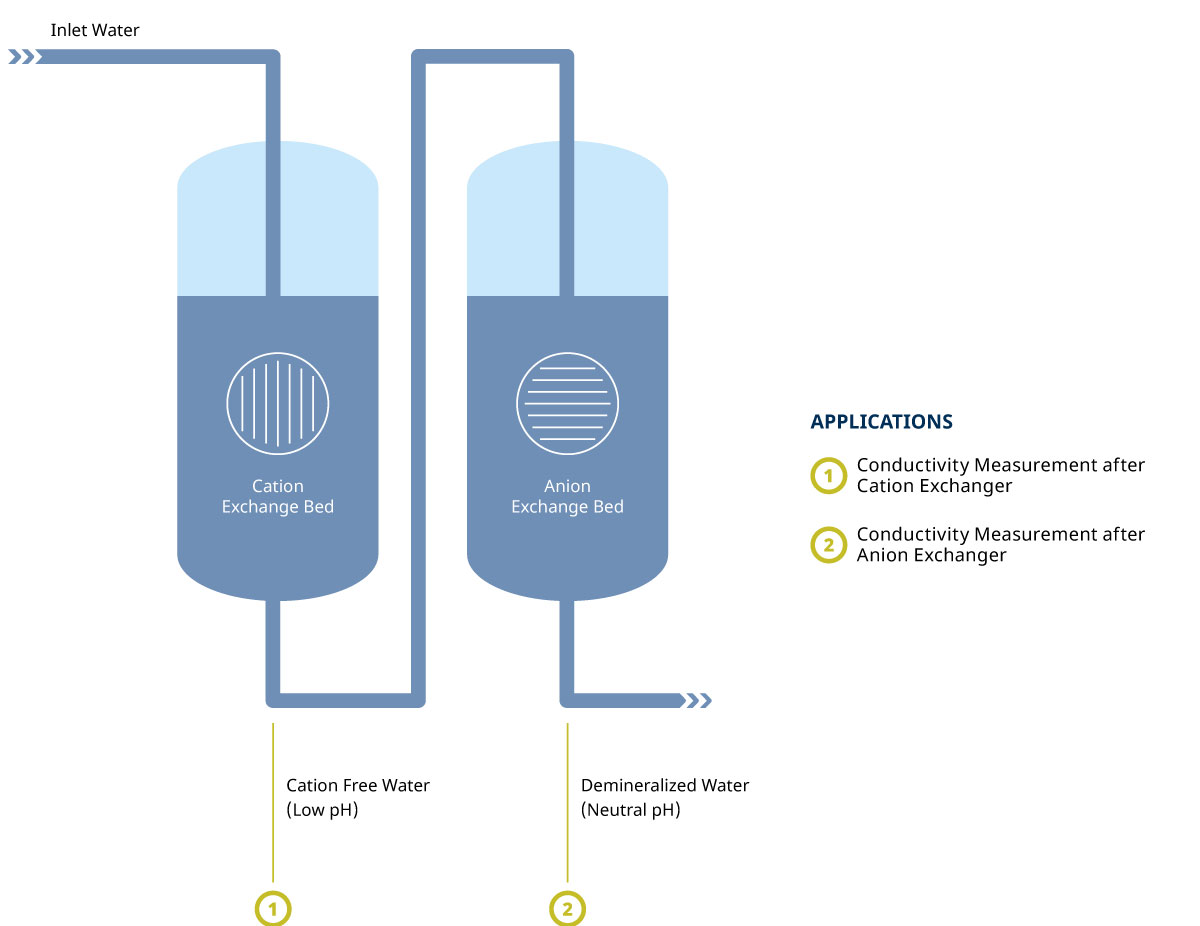

To produce pure boiler feed water, an ion exchanger with cation and anion tanks and a mixing bed for subsequent polishing can be used as an alternative to a reverse osmosis system. Pressure vessels made of steel and filled with ion exchanger resins absorb all the salt components (cations and anions) from the feed water. Ion exchanger resins must be regenerated using strong acids and alkalies.

Key Facts About the Application

Sector

Production of pure boiler feed water

Application

2 applications (1. Conductivity measurement downstream to the cation exchanger, 2. Conductivity measurement downstream to the anion exchanger)

Measured Parameters

Conductivity

Main Requirements

Measurement in water with low and neutral pH value

Measurement in Cation-Free and Demineralized Water

Description of application

Conductivity and cation conductivity must be measured downstream to each vessel. In order to reduce total costs and shorten the downtime required for regeneration, these measurements are obligatory for efficient system operation.

Requirement of the application

The amount of chemicals used and

wastewater produced can be minimized through optimized management.

Why Knick?

The conductivity sensor recommended for this application, SE604 from Knick, is the only sensor with removable outer electrodes for easy cleaning and handling. SI/SF (system integrators/system manufacturers) and plant manufacturers appreciate our reliable, well-designed, and precise solutions.