PROCESS ANALYTICS

Reverse Osmosis Systems

Reverse Osmosis Systems

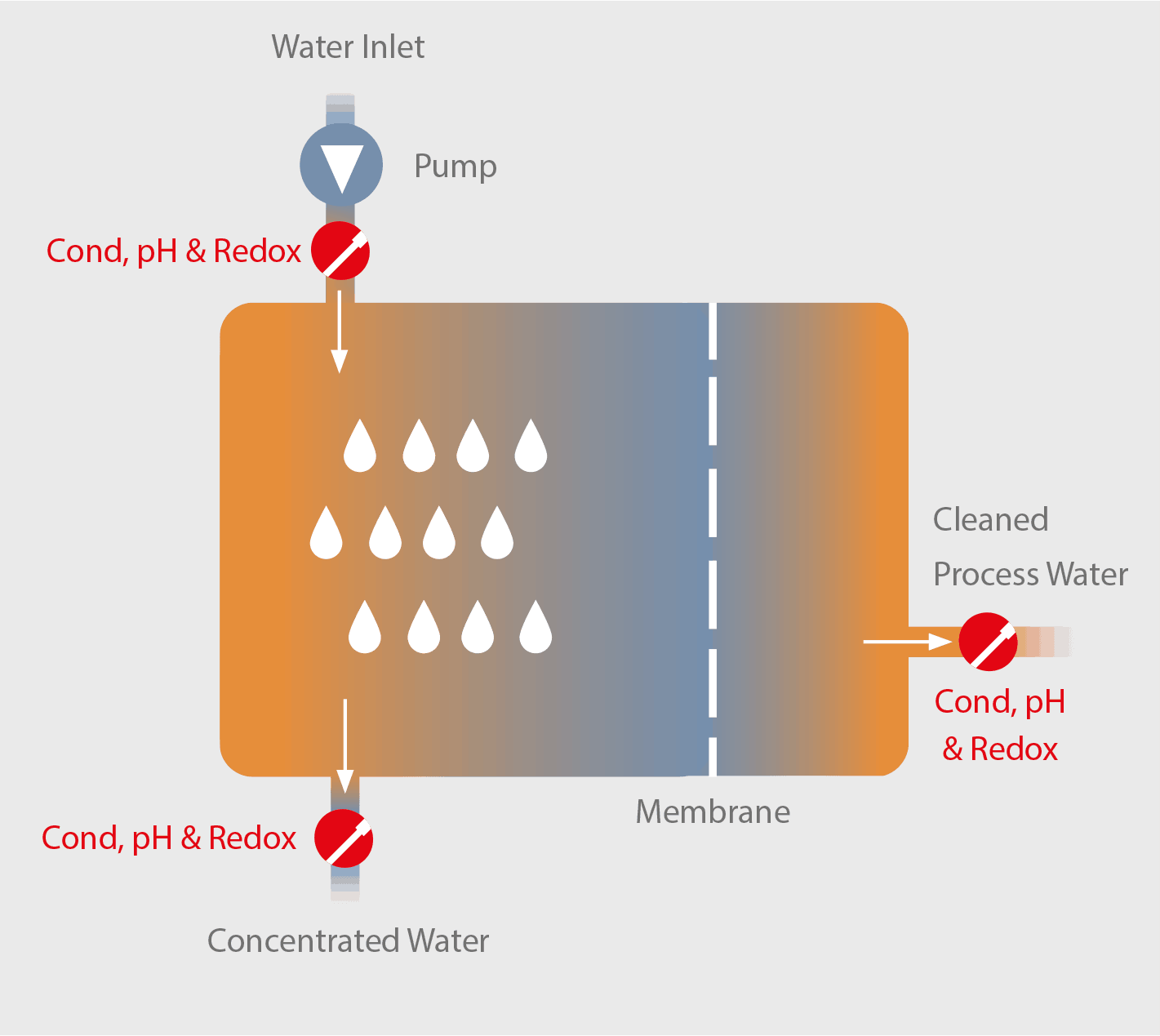

Reverse osmosis (RO) systems are used for water treatment in many industrial applications. In reverse osmosis, dissolved salts are filtered out of the water, and contaminants and even nanoparticles (bacteria and viruses) are removed. This process is used for the treatment of ultra-pure water for power plants and drug production, as well as in drinking water treatment and water desalination.

Key Facts About the Application

Sector

Reverse osmosis systems

Application

3 applications (1. pH loop for verifying permeate quality, 2. Conductivity loop for verifying module leakage, 3. ORP loop for verifying concentrated water)

Measured Parameters

pH, conductivity, and ORP

Main Requirements

Inline measurement of pH value, ORP, and conductivity

Measurements in Ultra-Pure Water and Concentrated Water

Description of application

In power plants, the reverse osmosis system is used to produce boiler feed water for steam generation. The diagram shows a typical boiler feed water system with RO technology. pH value, redox potential, and conductivity must be monitored after every RO step and in every RO segment in the main collection pipe.

Requirement of the application

Reverse osmosis monitoring systems require the inline measurement of pH value, redox potential, and conductivity. Adding various chemicals during the process prevents organic or inorganic deposits from adhering to the osmosis membrane. If metering is not precise, the membrane can be damaged and favorable conditions for biological growth may be established. Consequence: The systems must be shut down and cleaned in a complex process. The option to measure conductivity values in the micron range and the setpoint deviation of redox potential and pH value is one of the main prerequisites for extending the service life of the membrane and saving the costs of early replacement. The quantity of chemicals used, including chlorine and sodium bisulfite, can be significantly reduced when conductivity, pH value, and redox potential are precisely measured.

Why Knick?

The SE604 conductivity sensor from Knick is the only sensor with removable outer electrodes for easy cleaning and handling. The recommended pH sensor, SE558, has an electrolyte reservoir for accurate, stable measurement in probes with low conductivity. The greatest flexibility possible with Knick transducers (e.g., Stratos Multi): one system for all measuring loops with flexible configuration.

Associated Products

Associated Industries and Applications

Overview of specific applications and product solutions in different areas of power plants.