过程分析

冷却水系统

冷却水系统

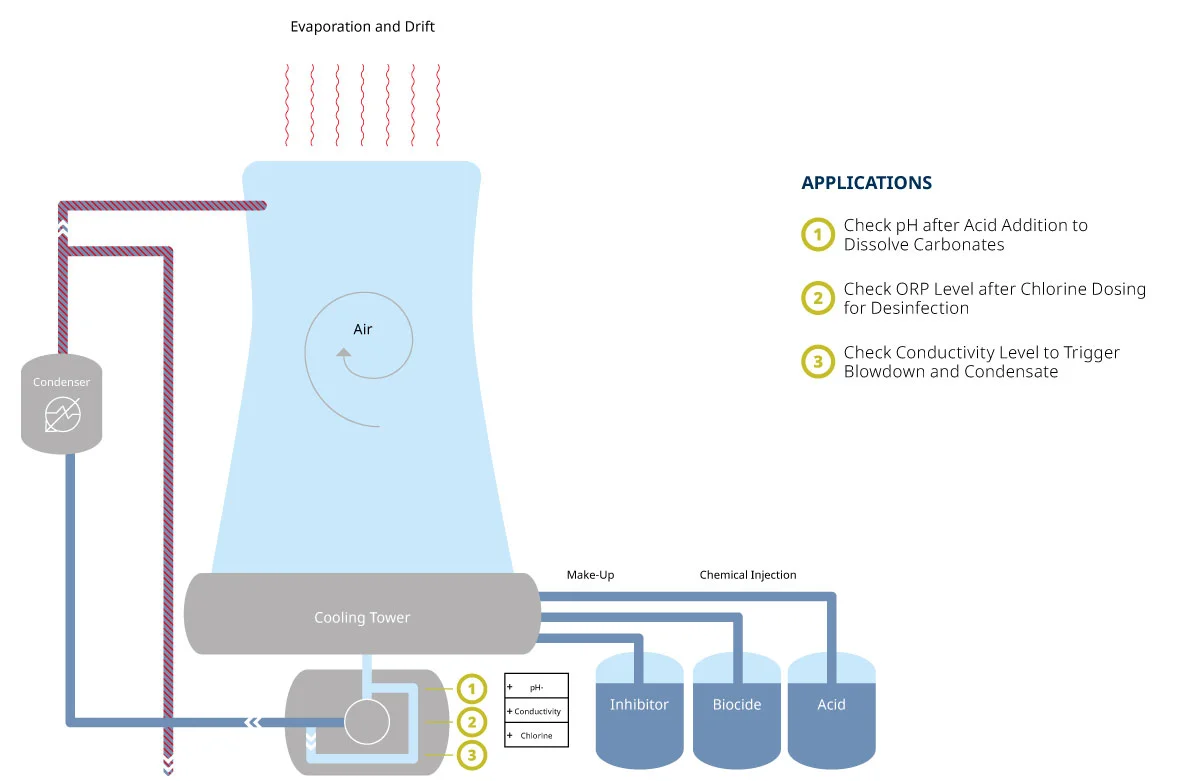

在火力发电厂中需要有效的冷却系统,将用过的蒸汽在汽轮机后转变为液态冷凝水(冷凝器)。为了使冷却系统经济高效地运行,需要进行复杂的化学水处理。冷却塔的设备和运行成本很高,必须尽力维护,以避免整个发电厂发生代价高昂的停机损失。这方面的主要困难是结垢、腐蚀以及藻类和细菌的生物生长。

主要应用概况

领域

联合运行的发电厂

应用

多个测量回路上的 3 种应用(1. 检查溶解氧 DO,2. 检查 pH 值和电导率,3. 检查电导率)

测量参数

pH、电导率和氧化还原

主要要求

锅炉结垢、腐蚀、藻类和细菌引起的生物生长。

介质中的酸和生物杀灭剂。

在冷却水中测量

应用说明

应用 1:

在碳酸盐阻塞系统之前加入酸使之溶解,通过 pH 值测量进行控制。

应用 2:

加入生物杀灭剂(如次氯酸盐)以抑制阻塞系统的藻类和细菌的生长,通过氧化还原测量进行控制。

应用 3:

必须每隔一段时间进行排污。用干净水替换污染严重的冷却水,以降低化学物质浓度,通过电导率测量进行控制。参见包含测量参数和测量点信息的附带原理图。

借助 Knick 非接触和感应式 Memosens 技术,可避免潮湿和腐蚀引起的维护问题。在实验室远程校准传感器,并能在现场轻松更换传感器,这有助于用户顺利操作系统,无需进行困难且耗时的现场校准。

应用的要求

- 锅炉结垢、腐蚀、藻类和细菌引起的生物生长。

- 介质中的酸和生物杀灭剂。

为何选择 Knick?

Knick 开发有可扩展的模块化连接件系统,采用耐腐蚀性极强的材料和适用于苛刻条件的传感器。使用多功能 Stratos Multi 工业变送器,可以用一台设备监测各种参数。